Welcome to REFRAMED, our online magazine! Get to know the Dürr brand from a new perspective, and discover what lies behind our promise of “Leading in Production Efficiency.”

Explore fillers and subject areas

Discover Dürr

-

IN THEFRAME

3 questions with

3 questions withThomas Hohmann

Global Business Unit Head LIB -

What motivates you in your new role?I want to create the conditions for a dedicated team to thrive in a difficult market and, at the same time, secure a sustainable, future-proof business for Dürr.

-

What does the move from LIB to the Automotive Division mean?The expertise and established structures available in the AUTO division offer LIB synergies and improved processes. Both strengthen the competitiveness of the business unit.

-

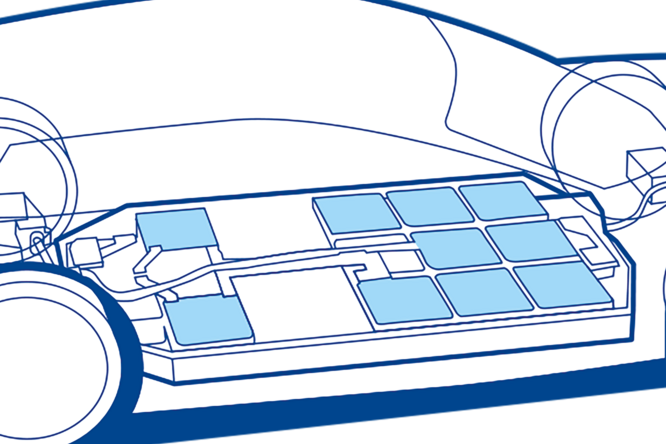

What opportunities do you see for the LIB market?We need to bring our dry coating technology to market maturity, gain a foothold in the Asian market, and address additional customer segments such as energy storage in order to grow again.

What strategic orientation is mentioned in the “Paint Shop of the Future” concept?

fixed lines with rigid cycle time

compact standard cell without expansion

modular box concepts with flexible scalability

centrally controlled mono system

Read more

Back to Quiz

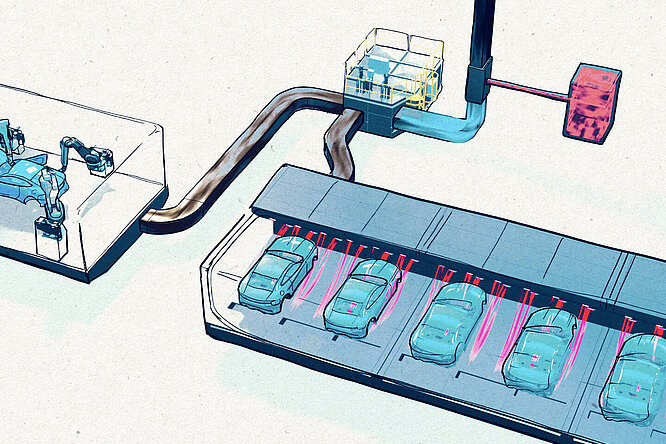

The paint shop of the future breaks with the traditional layout in automotive engineering and relies on a modular concept.

Instead of being painted in a line, the body parts are now painted in boxes. These are scalable and therefore suitable for a wide variety of sizes and applications. Instead of fixed cycle times, there are demand-oriented process times.

Discover Dürr

-

IN THEFRAME

3 questions with

3 questions withThomas Hohmann

Global Business Unit Head LIB -

What motivates you in your new role?I want to create the conditions for a dedicated team to thrive in a difficult market and, at the same time, secure a sustainable, future-proof business for Dürr.

-

What does the move from LIB to the Automotive Division mean?The expertise and established structures available in the AUTO division offer LIB synergies and improved processes. Both strengthen the competitiveness of the business unit.

-

What opportunities do you see for the LIB market?We need to bring our dry coating technology to market maturity, gain a foothold in the Asian market, and address additional customer segments such as energy storage in order to grow again.

Show more