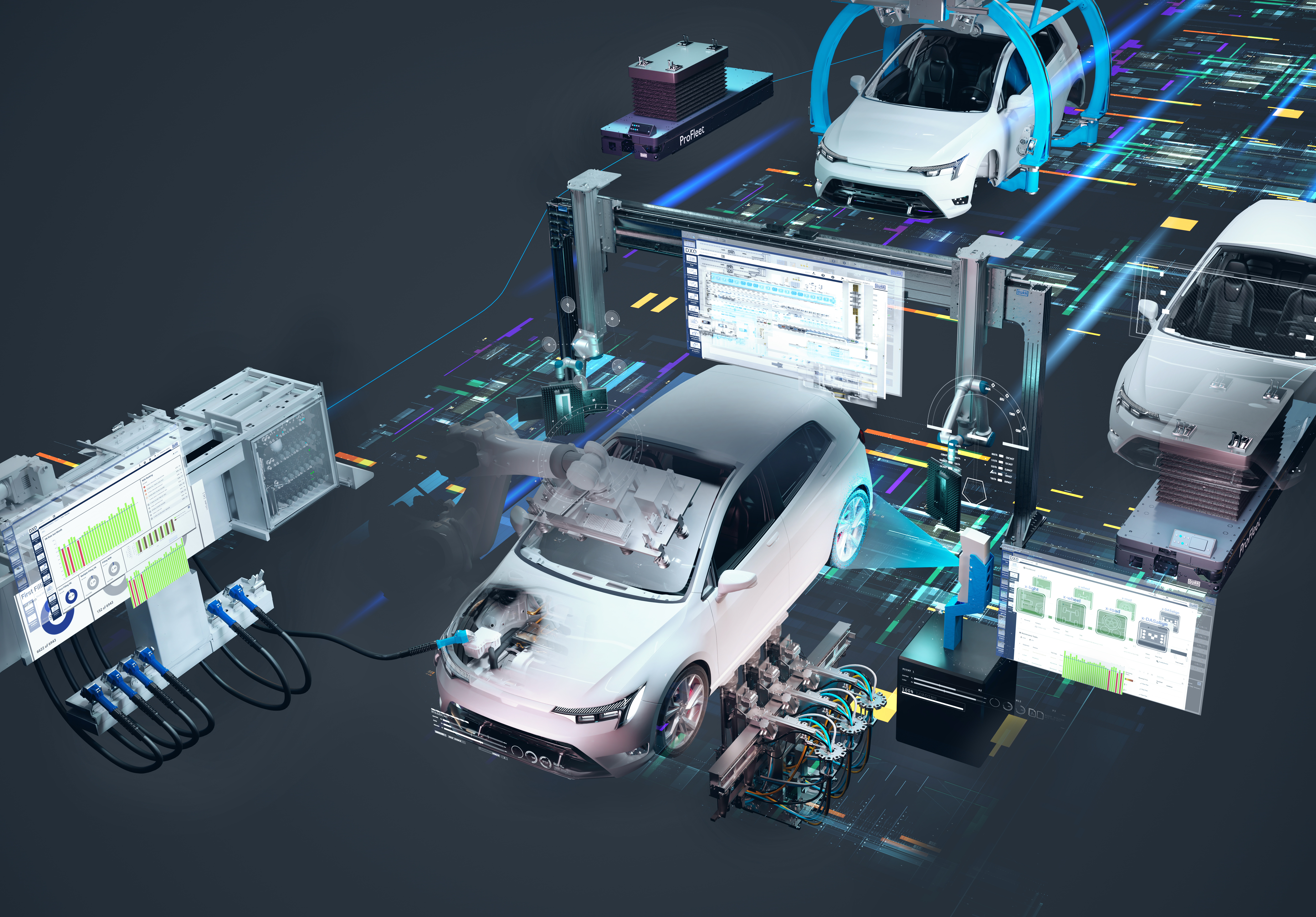

Smart data for smart production

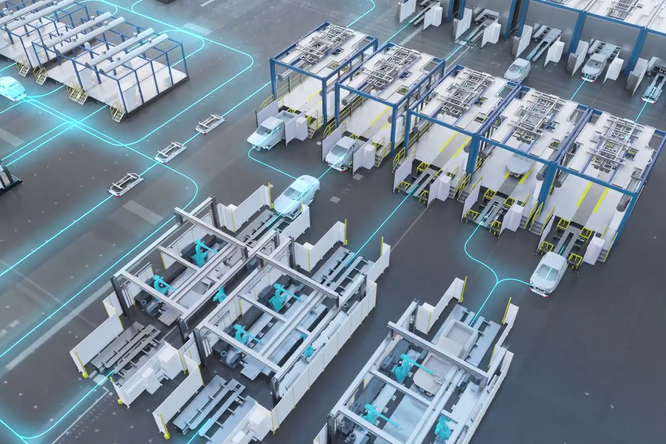

Dürr's software approach is based on the individual products in its portfolio complementing each other to create a continuous data pipeline – from high-resolution machine data to plant-wide production data. The latest development enables customers to work with high-frequency data throughout the entire manufacturing process, turning big data into smart data. “Our DXQanalyze products process the collected data in fractions of a second, giving our customers real-time insights into production,” explains Walter Schubert, Senior Product Manager at Dürr.

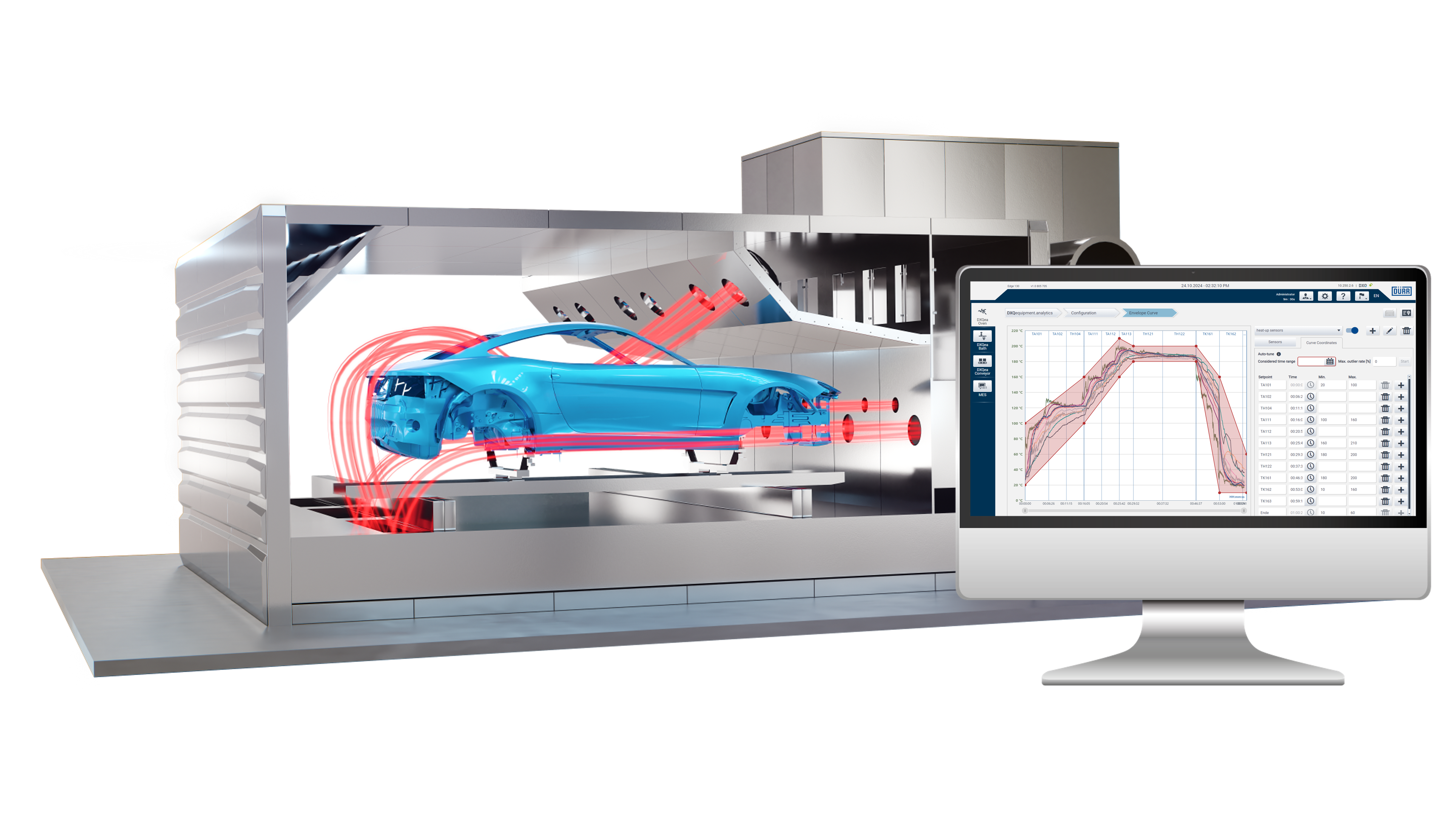

Use case: Paint shop: Process transparency

An unplanned conveyor system stoppage in the dryer regularly causes problems: if the car bodies remain in the dryer for too long, this can have a negative effect on the coating quality. In this case, each car body must be laboriously checked manually and, in the worst case, scrapped. The DXQ software brings transparency to this worst-case scenario by giving each car body a digital fingerprint. Based on process parameters, the software generates real-time heating curves at different positions for each car body and evaluates them according to customer-specific quality criteria. Together with the workpiece-related information, this creates a long-lasting quality data file for all vehicles, which helps to make concrete quality statements. The DXQequipment.analytics software is already being used successfully by various OEM customers.

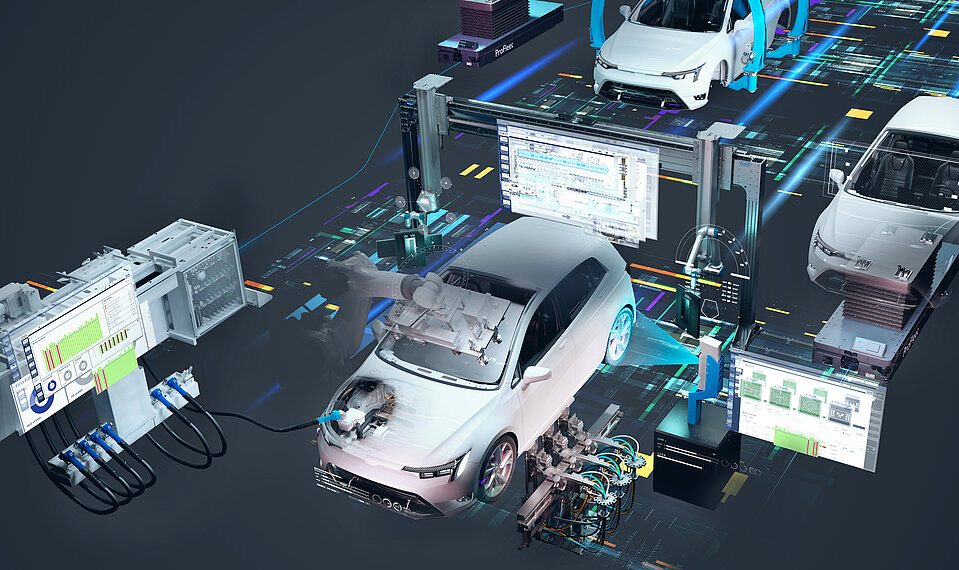

Use case: Final assembly – reduction of rework time

The rear axle is adjusted during vehicle pre-assembly. These parameters are checked again during final end-of-line testing. Fluctuations or deviations in the body-in-white and the assembly line can lead to systematic differences, meaning that the settings are no longer within the target range. This prolongs the adjustment process or leads to rework. With the help of DXQvehicle.analytics for testing, these regularly occurring errors are identified. In addition, automatically calculated correction values can be transferred centrally to the rear axle adjustment system via the web interface, thereby improving adjustment accuracy in advance. This can be done on a type- or system-dependent basis. This DXQ solution significantly reduces rework times.

Data security in focus

At Dürr, security measures are integrated into the core architecture at an early stage of the development process (e.g., Secure by Design). This ensures compliance with security regulations such as the AI Act or the NIS2 Directive. “In short, we are also well prepared for upcoming security requirements such as the Cyber Resilience Act (CRA),” emphasizes Schubert.