Sealing rethought

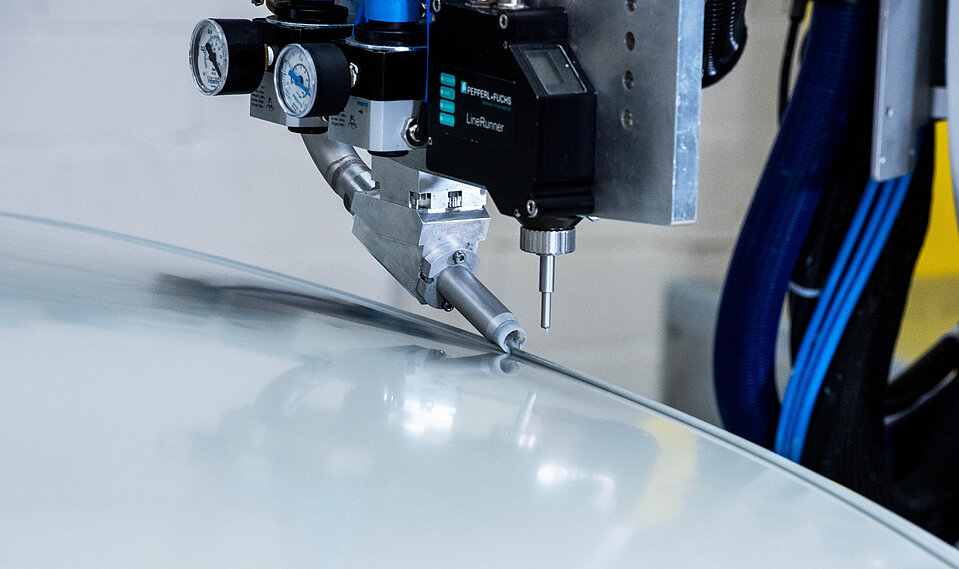

Sealing can get tricky. For example, the engine compartment or headlamp housings, tests automation limits. Likewise, when contours, drill holes, or bolts make automatic PVC application difficult, Dürr overcomes these challenges with a wide range of flexible applicators and specialized nozzles.

We work with our customers in our own sealing test centers to determine which solution is best suited to their needs. This ensures that everything runs smoothly later in series production.

Martin Wolf

Manager of the Sealing Test Center, Dürr Systems AG

No more tedious overhead work

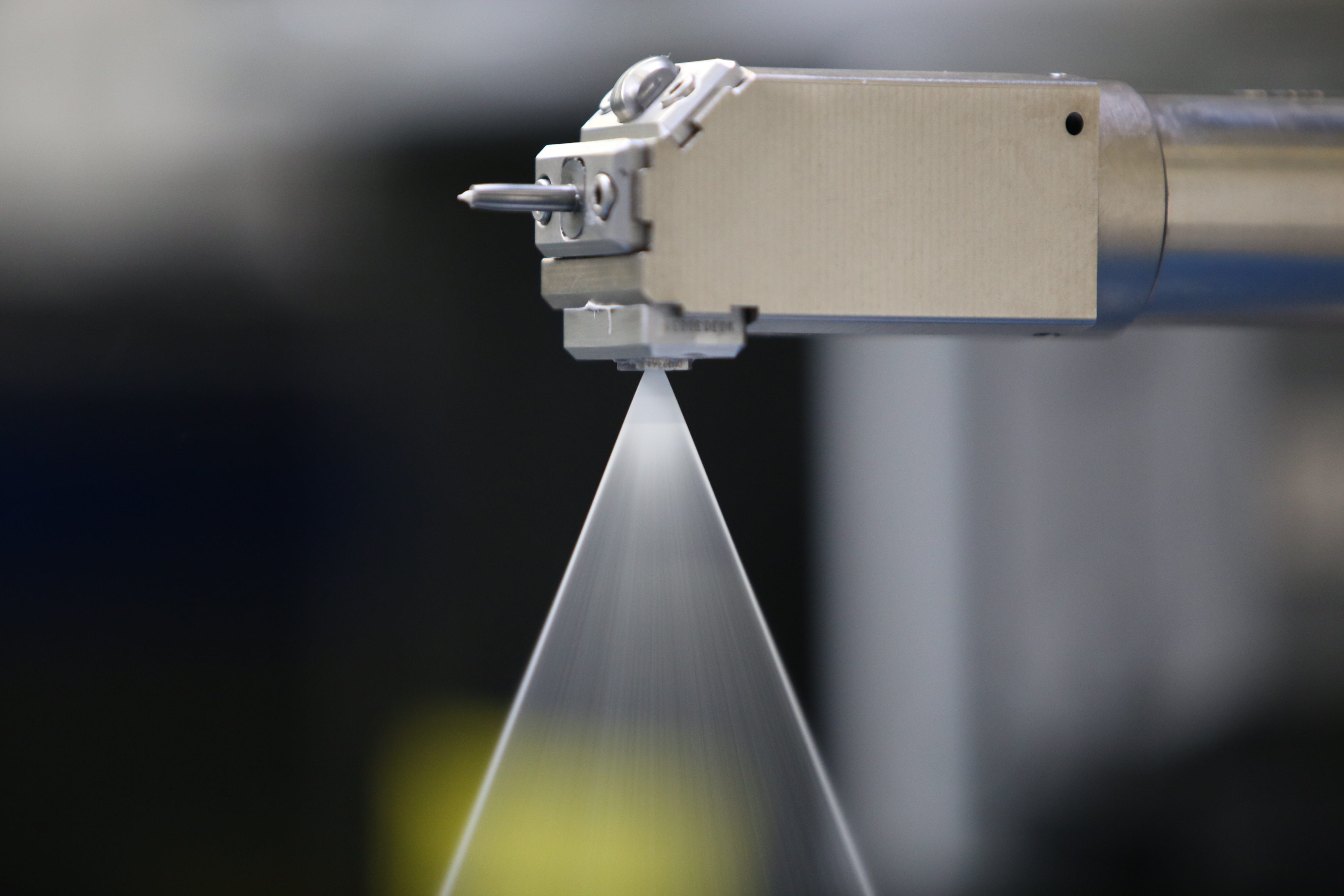

Tasks that continue to be performed manually today, —such as masking small areas or protecting bolts with sleeves,— can be automated. The potential of this approach is evident right from the first step of the sealing process, underbody sealing: EcoJetAC eliminates the need for time-consuming masking and the subsequent removal of adhesives and sleeves. Instead, Dürr's air nozzles do the work – they automatically clean the underbody with compressed air and reliably remove excess PVC from bolts.

Achieving high quality underbody sealing automation is simple: EcoJetAC can be easily retrofitted to the EcoGun2 3D applicator and flexibly combined with other nozzles. In combination with the EcoJetSE wide slot nozzle, which applies PVC over large areas without overspray, not only does the process become more efficient and eliminates the need for a separate cabin with air supply and filter systems. This is a major step towards a sealing process that does not involve physically demanding work while offering maximum efficiency.

It often makes sense to approach automation step by step—for example, during a model change or when cycle time is still available. Individual components can be easily retrofitted and immediately provide noticeable relief.

Martin Wolf

Manager Test Center Sealing, Dürr Systems AG

After underbody protection, the car body moves from the overhead conveyor on to the skid. This is called the “seam-from-above area”. Here, robots work at eye level with the car body and reliably apply the coating to the interior, engine compartment, exterior of the vehicles, and roof seams.

The hem flanged seams of the doors and flaps are usually apply sealant when the doors and flaps are closed. Amazingly, a 3 millimeter wide gap is wide enough for Dürr nozzles to enter the area to apply sealant to the doors and hoods from behind. However, to apply seam sealing in the entry area, engine compartment, or trunk, the doors and flaps must be opened.

This can also be automated with robots from Dürr.

Sprayable insulation materials instead of insulation mats

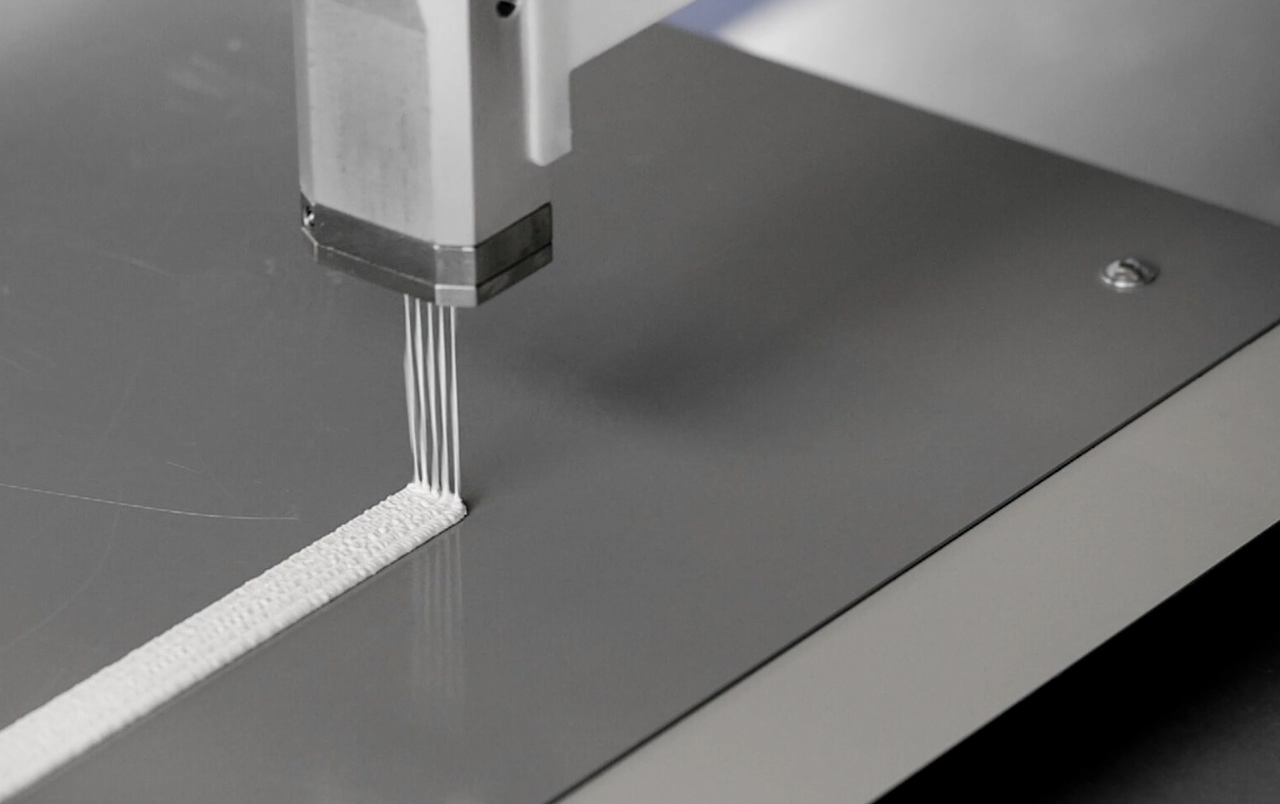

The so-called “seam-from-above area” also includes insulation application, —another area in which automated processes are gradually replacing manual tasks. Instead of manually inserting insulation mats, robots apply sprayable insulation materials, known as Liquid Applied Sound Deadener (LASD). The LASD materials are applied in strips up to 100 millimeters wide precisely onto sound-critical panels in the engine compartment or floor area, providing effective noise suppression. Dürr supplies the appropriate technology: a material specific LASD nozzle, which is supplied with sound deadening material by the EcoShot Meter dosing system. The EcoShot Meter dosing system is available in both single tandem versions.

Interior sealing requires a delicate touch, or in other words, millimeter-precise technology. Since doors and tailgates remain closed, Dürr must use its long robot arms to reach into the body through window cutouts to cleanly seal sheet metal edges. Dürr offers close-fitting hose packages that enable entry into the body’s small cutouts, that otherwise would not have been possible, while enabling the robot's freedom of movement as much as possible.

For fine seam applications (FAD), Dürr offers special nozzles in many lengths and contours. Together with the EcoGun2 3D applicator, these nozzles apply PVC to seams with extremely high standards for uniformity and surface quality to seal sheet metal folds.

When things get tight and delicate, the EcoSealJet Pro shows its strengths. The droplet applicator is particularly suitable for very flat beads and complicated geometries with tight curves. Its five main needles produce smaller and larger droplets independent needle control of frequency, stroke, and trigger time. The needle movement essentially “shoots” the droplets onto the vehicle. The result: precise seams without material buildup and reduced rework.

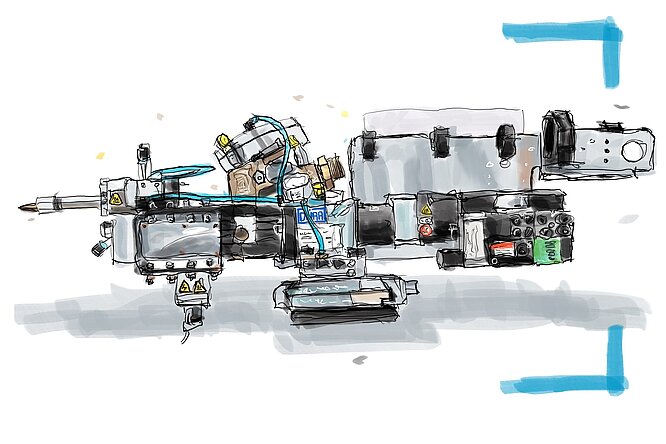

EcoGun2 3D and EcoSealJet Pro cover all car body sealer application areas

Which applicators are used for sealing, either the EcoGun2 3D through its wide variety of nozzles, or the EcoSealJet Pro, depends on the shape of the car body, accessibility, and the specific application. The most versatile is the EcoGun2 3D: thanks to its modular applicator that can be equipped with up to three nozzles and various attachments. This enables a highly flexible range of applications – ideal for numerous use cases, from spraying insulation mats to fine seam sealing.

The flexible EcoGun2 3D is perfect for most applications. For delicate applications on vehicles, we have developed the EcoSealJet Pro, which applies the finest seams with maximum precision. Our offline department is able to examine accessibility in advance and determine the perfect position of the robots in relation to the car body.

Martin Wolf

Manager Test Center Sealing, Dürr Systems AG

Roof seam application: Vacuum nozzle and skiving

Dürr's toolbox also enables a fully automated process for the roof seam application, i.e., the connection between the roof and side panel. A special vacuum nozzle smooths the seam. Like a vacuum cleaner, it sucks up excess material without the need for manual reworking of the seam. The result is so smooth that it is barely visible after painting.

Dürr also offers a smart solution for vehicle roofs with bonded panoramic glass roofs: “skiving,” i.e., automated scraping of the sealing seam, replaces manual processing. A specially developed squeegee attached to the EcoGun2 3D flattens the PVC seam precisely. This allows the glass roof or windshield to be bonded reliably with a perfect fit.

Dürr also thinks in terms of full automation at the end of the sealing process, for example in rocker panel coating. The specially developed EcoJet SE wide slot nozzle coats the sill with PVC without overspray. Unlike the conventional method using the EcoGun2 MD applicator, which also applies the material with sharp edges using a template, EcoJet SE does not require a booth, but applies the PVC with virtually no material loss.

Automating post-processing is the final step on the path to a fully automated sealing line. Only when manual smoothing and cleaning are no longer necessary will we achieve 100 percent automation and thus maximum efficiency, quality, and process reliability.

Martin Wolf

Manager of the Sealing Test Center, Dürr Systems AG

Manual rework may still be essential in the sealing process, especially to compensate for sheet metal tolerances within the body. Visual inspection, spreading, and brushing are therefore still part of everyday work. This is precisely the application for the next major potential for automation: in the future, smart camera systems are to be used to detect deviations in the car body and the sealant application to automatically initiate appropriate corrections. This brings a fully automated sealing process within reach.