Challenging dimensions

In the new production facility, both ICE and electric cars are to be painted on one line each to start with. What is special is that both painting lines are designed so that a switchover to exclusively electric vehicles is possible in the future.

Hagen Rebmann was responsible for the major contract in Anting as Dürr's project manager. He oversaw everything – deadlines, costs, and responsibilities – from the Dürr headquarters in Bietigheim. He received crucial support from a project team on site that was responsible for installing the plant and managed the commissioning. One of the biggest challenges during the assembly was the shortage of storage space in and around the building. All the components had to be delivered just in time; a major logistical effort. For about three months, up to 100 trucks per week arrived at the site. The employees at Dürr’s Shanghai-Qingpu site also found their hands full once the contract was awarded. They manufactured many components of the paint shop itself, including nine Oxi.X TR air pollution control systems as well as the entire painting booth housing.

Contract scope

→ RoDip® M

→ Ecopaint WetSystem

→ Ecopaint Oven

→ Ecopaint Booth

→ EcoDryScrubber

→ Paint supply

→ PVC supply

→ Oxi.X TR

→ Sorpt.X CD

→ DXQcontrol

→ DXQequipment.analytics

→ DXQplant.analytics

→ DXQmaintenance.analytics

The scope of work comprised all of the plant technology, including the RoDip® dip coating system, painting booths with EcoDryScrubber dry separation, and ovens. Right from the beginning, mechanical engineering and IT expertise went hand in hand. Digital solutions were developed in parallel with planning and implementing the comprehensive plant engineering. For example, the specialists from the Dürr Digital Factory transformed the paint shop into a smart factory with a series of software products from the DXQ portfolio. The DXQequipment.maintenance and DXQplant.analytics applications will help with maintenance and optimization of the entire plant in the future. SAIC Volkswagen also implemented the entire bandwidth of the DXQcontrol product series. The plan is to use the higher-level control technology in Anting not only in the paint shop but also in the body shop, as well as in the high-bay warehouse, the assembly shop, and the production of battery systems in the future.

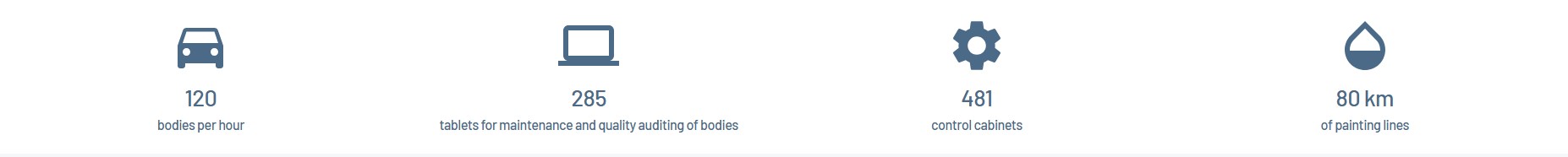

A further innovation is the use of mobile apps provided by various DXQ products. For example, employees can manage and filter alarm functions directly at the point of origin in the plant using tablets if the line comes up to a stop.