Well Balanced

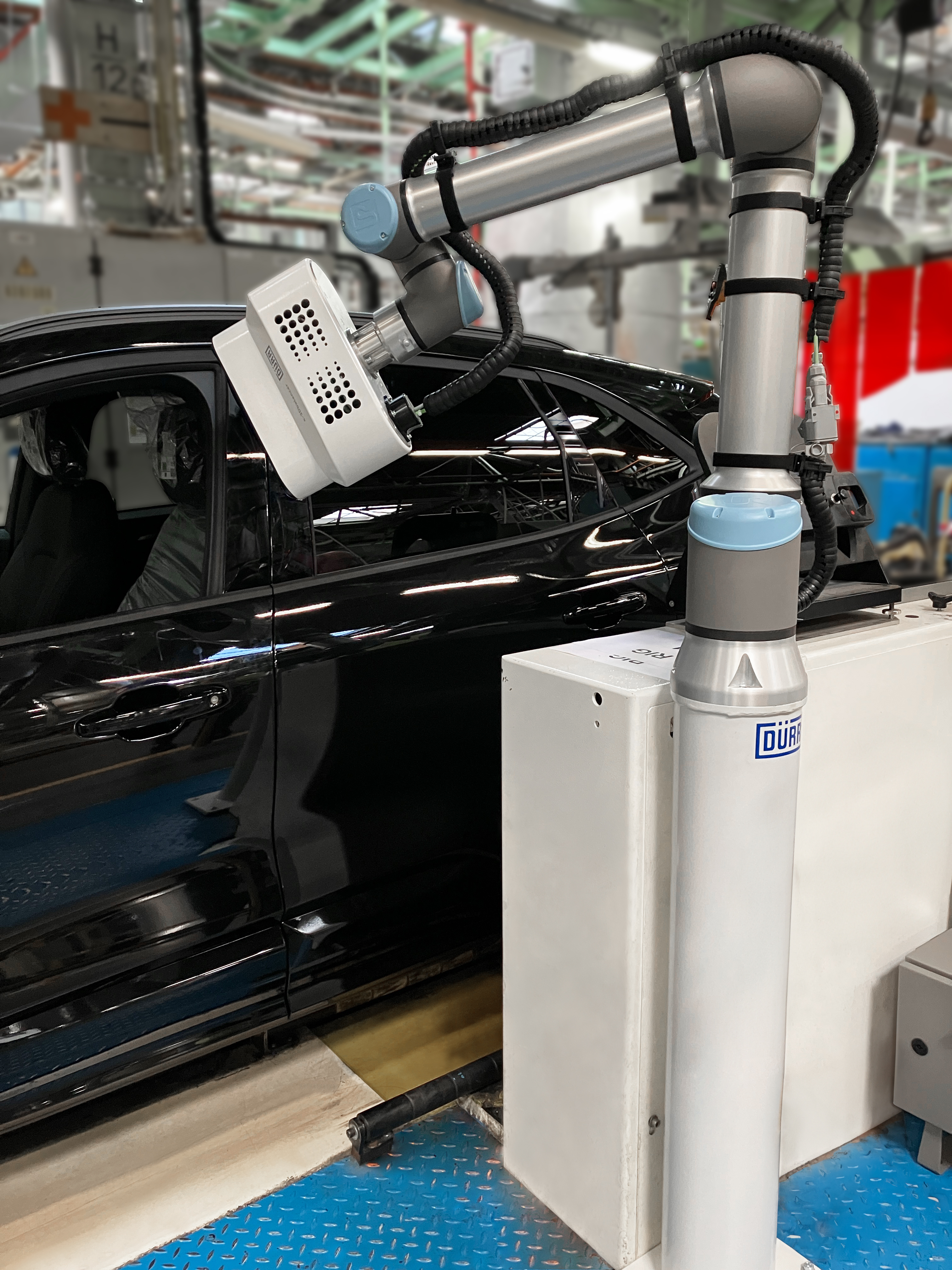

The correct position of the steering wheel plays a crucial role in chassis measurement. It ensures that the steering wheel is aligned when driving straight ahead after the chassis has been adjusted. Conventional steering wheel balancers are manually inserted into the steering wheel to measure the steering wheel angle. Once the work is complete, they must be removed again. This process is not only time-consuming, but also prone to errors: incorrect insertion, accidental bumping or dropping can affect accuracy and even cause damage to the vehicle.

The x-3Dbalancer optical steering wheel balancer uses a high-resolution 3D camera in combination with intelligent software to accurately detect the steering wheel position – without any mechanical contact. Instead of manual intervention by a mechanic, a collaborative robot positions the sensor at the open side window, making the measurement process fully automated.

The technology is flexible in use and largely independent of vehicle and steering wheel design.

By combining optical measurement technology and robotics, the x-3Dbalancer creates ideal conditions for efficient, error-free, and future-oriented chassis adjustment in series production. The system not only reduces effort but also increases process reliability and quality – a real step forward for modern automotive production.