Stellantis Kenitra: Efficiency meets sustainability

The project team included employees from Dürr China, led by Yu Gavin, alongside a robotics team from Dürr France. David Sturnich, Key Account Manager at Dürr, supported the project from the very beginning: “I had the opportunity not only to be involved in the bidding phase, but also to support our Chinese colleagues during implementation. That was a personal highlight for me.”

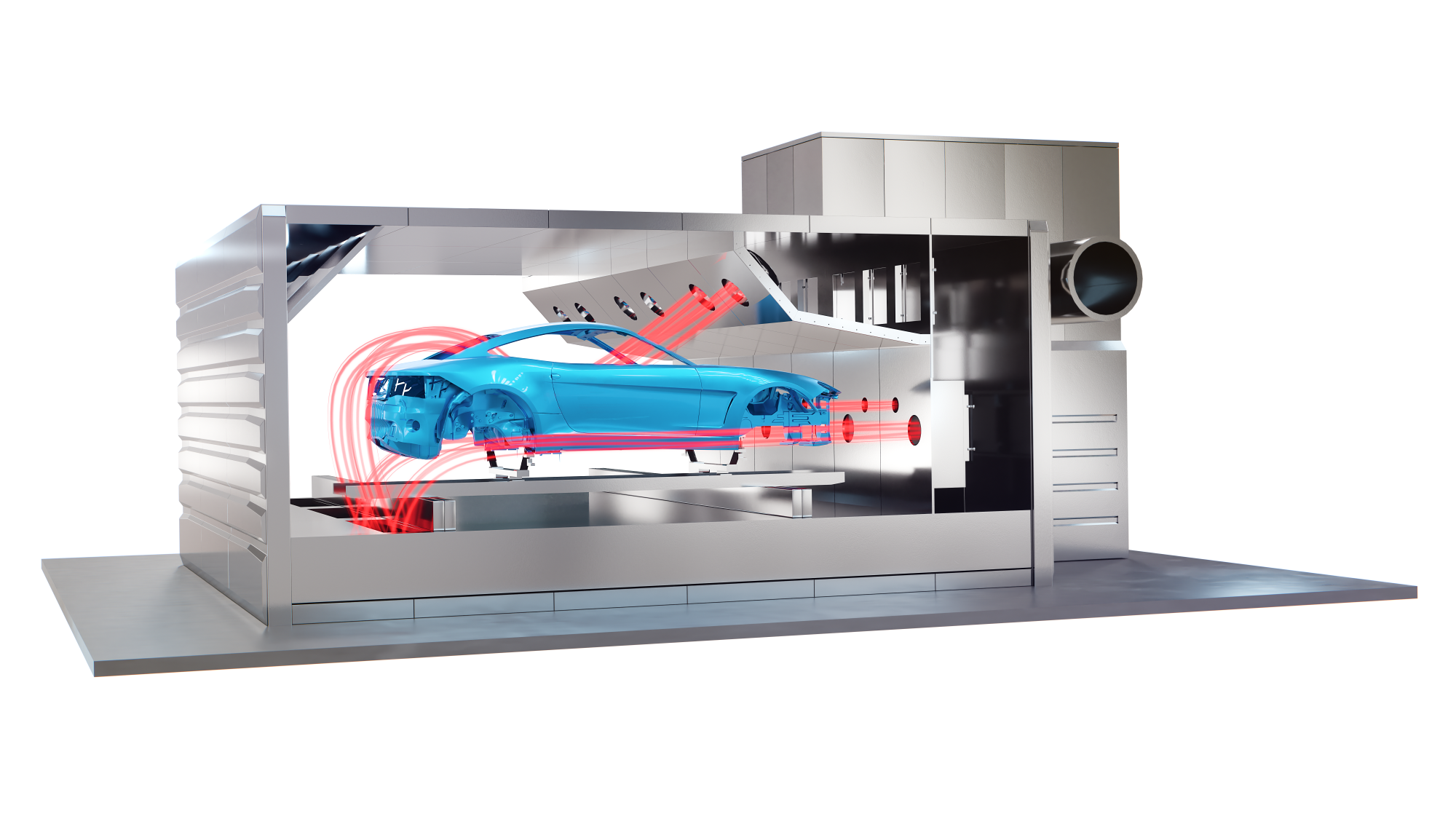

The new paint shop doubles the site’s capacity, designed to process 30 car bodies per hour matching the first plant Dürr built at this location in 2019. Featuring the patented RoDip® rotary dip process and the EcoInCure electric dryer, used for the first time at Stellantis, the plant establishes new benchmarks in resource efficiency and CO₂ reduction. The EcoInCure dryer reduces emissions by up to 40 % compared to gas-powered variants.

Reused instead of newly purchased

Another key feature: the plant incorporates painting robots and application technology reused from existing Stellantis plants – an excellent example of sustainable production. “Reusing equipment is not only resource-efficient, but also a clever way to deliver a high-performance painting plant within a tight time and budget frame,” says Sturnich.

The project faced challenges from the outset: “We had a very tight budget and challenging time schedule, especially with necessary transport lead time from China,” recalls Sturnich. “But in the end, it was a complete success – in terms of quality, timing, and costs.”

A major milestone was reached on October 1, 2025, when the first car body was painted – a moment that made the team proud and demonstrated the progress of the project. Commissioning went smoothly, and customer feedback has been consistently positive. Even after the project’s completion, Kenitra 3 continues to make an impact: the technologies used, particularly RoDip® and the EcoInCure electric oven, are attracting great interest from Stellantis for future large-scale projects.