SMART MAINTENANCE FOR AGVS

DXQequipment.maintenance is Dürr's maintenance software for all production equipment in the paint shop and final assembly. One example is the application for AGVs, which we look at in more detail in this article.

AGVs – Flexibility for production

AGVs are driverless transport systems that effortlessly transport car bodies, materials, and other goods. With their 360-degree maneuverability, AGVs break up rigid production lines and make the manufacturing process particularly flexible and precise. Each ProFleet AGV from Dürr can be individually tailored to the respective workpiece: a tailor-made solution for every requirement – AGVs transport everything that needs to be moved.

The advantages for automotive manufacturers are obvious: the systems are flexible and scalable, allowing the number of vehicles used and the routes to be adapted to new processes at any time. Direct routes between start and destination points reduce throughput times and increase efficiency in the production process.

Transparency and efficiency in maintenance

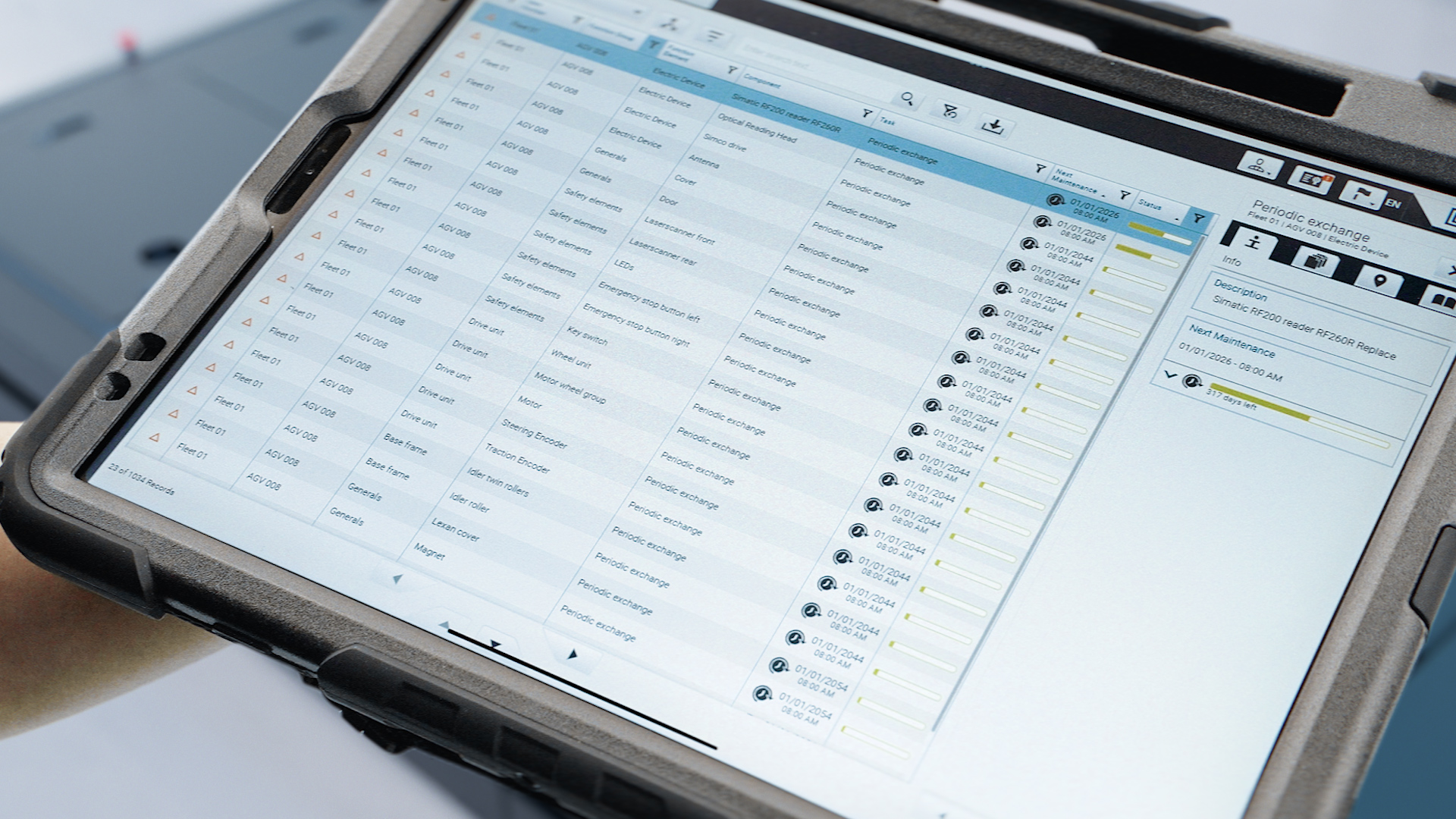

Typical maintenance tasks for AGVs include cleaning the traction and steering engine, checking and clearing the laser scanners, and periodically replacing the batteries. DXQequipment.maintenance for AGVs makes maintenance management easy and clear. The solution offers a user-friendly front end that displays all maintenance activities transparently. Operators can see the pending tasks at a glance and access the relevant documentation with just one click. This makes maintenance significantly more efficient.

More than just maintenance – a digital assistant

The software combines all relevant maintenance processes in one system. Preconfigured tasks make it easy to get started, while individual adjustments can be made at any time. Maintenance intervals can be set dynamically based on operating parameters such as operating hours or kilometers traveled. The system monitors when tasks are due and assigns them to the responsible employees. Thanks to mobile access options – whether via a browser view or a mobile device – maintenance management is available everywhere.

Operators can view the individual task history, status, and documentation, which ensures a high level of transparency and traceability. Your own documentation can also be stored here, so that the maintenance technician has all documents and information available centrally in one software program.

Benefits for OEMs

DXQequipment.maintenance offers significant benefits for automotive manufacturers. Monitoring all maintenance tasks with the intuitive and powerful software reduces unplanned downtime – an important factor in highly automated production environments. The solution ensures maximum transparency, as all maintenance activities are fully documented and can be accessed at any time. Thanks to its modular architecture, the software is scalable and can be easily integrated into existing IT landscapes, regardless of the size of the plant. In addition, progressive web app technology enables mobile use and supports multilingual task imports, simplifying implementation in international production networks.

With DXQequipment.maintenance, Dürr offers a high standard in digital maintenance management for AGVs. The time and material savings in the maintenance process also increase the availability of the AGVs and thus the overall equipment effectiveness – a decisive step on the way to a smart factory.

Discover the secret of the hard-working ProFleet AGVs and their optimal maintenance in the video: