Small surface, big potential

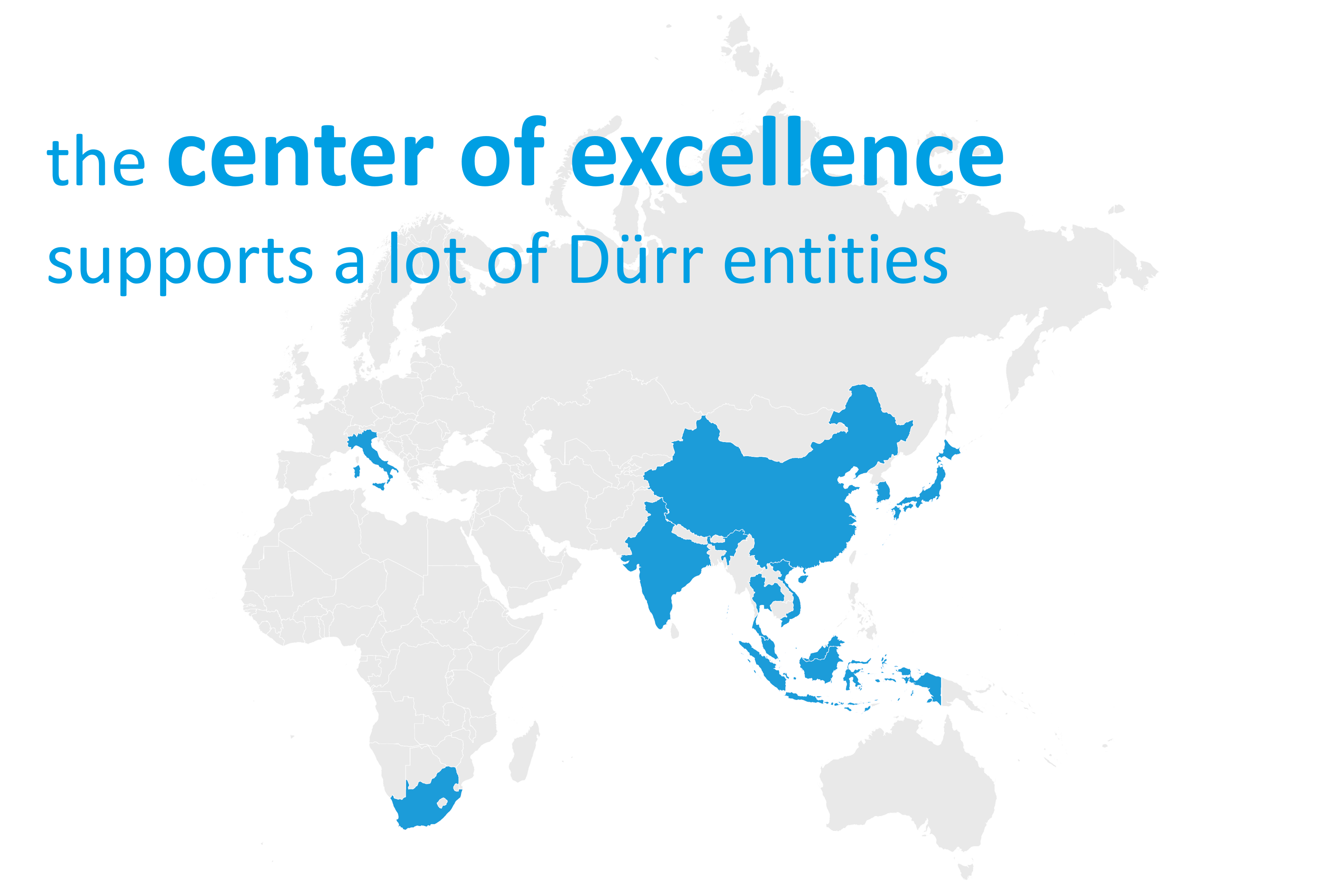

Is the painting process of motorcycles and cars the same? Not at all. Although the steps in the painting process are similar, there are several challenges and unique requirements that demand a precise approach. That is why Dürr's Center of Excellence has been in India, the largest market for two- and three-wheelers, since 2018. Over the years, Dürr India has developed into a key industrial partner, possessing extensive know-how and expertise and having implemented nearly all projects for Royal Enfield, TVS and Hero. Dürr India builds at least one paint shop per year and supports all other Dürr entities with local projects by sharing valuable technical knowledge. This support includes expertise during pre-sales phases, access to past project data, and optimized layouts for various capacities and processes.

Understanding the customer

It is important to the employees at Dürr’s Center of Excellence to understand each customer and their individual needs. This makes every project unique in terms of planning and execution. Thanks to many years of industry experience, Salim Babu, Director of Sales Automotive at Dürr India, knows exactly where the challenges lie for customers in the two- and three-wheeler industry: "Finding the right conveyor system is always a crucial point. Here, it is important to consider carefully whether a monorail solution, a skid solution, or a wagon-based system is best suited.“ Customers often ask for compact and scalable solutions. “Our tailor-made solutions such as EcoDCMACS and EcoDry Rack, combined with the innovative product solutions of the Dürr Group, such as DXQcontrol, already make us a respected partner in the industry," adds Babu.

The same yet different

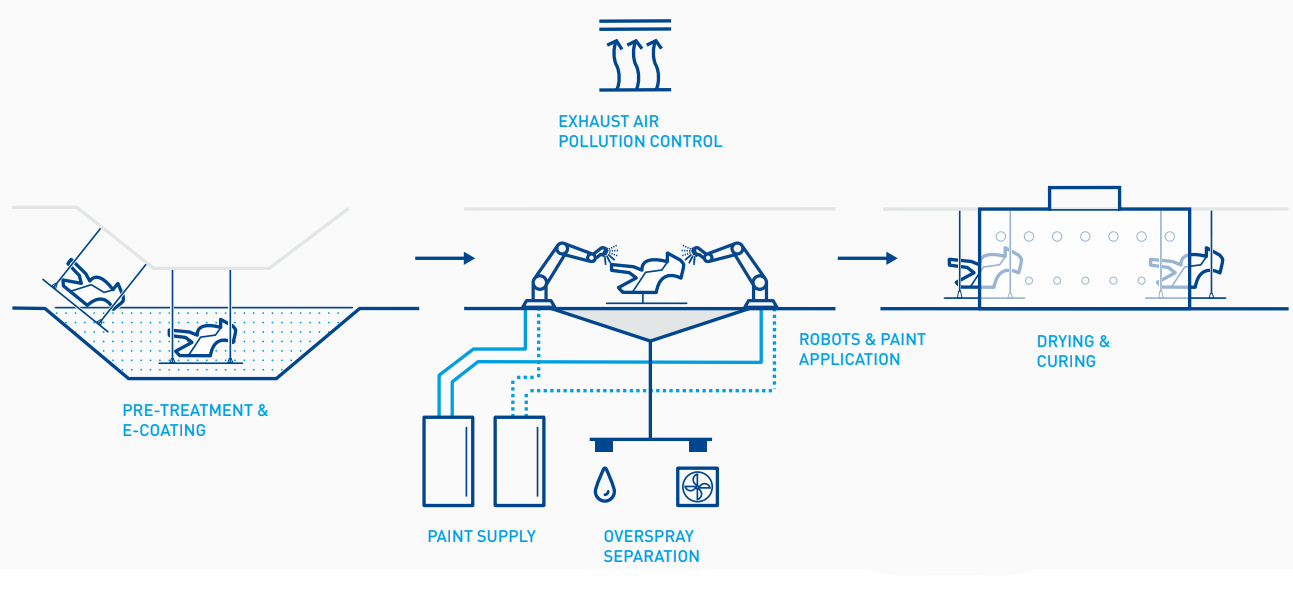

At first glance, there are no major differences in the painting process for cars, motorcycles, and tuk-tuks. The process begins with pretreatment and cathodic electrocoating to protect the body from corrosion and rust. After a trip through the dryer, the painting process begins. Dürr handles both the paint supply and application – either automatically or manually. Depending on customer requirements, overspray can capture using either wet or dry separation methods, with EcoDry X representing an environmentally friendly technology. Dürr offers the two- and three-wheel industry turnkey paint shop systems or, on request, individual process steps.

So, what is the difference compared to automotive painting? Higher volumes in the two- and three-wheeler industry result in faster conveyor speeds and increased overspray. At the same time, the paint surface is smaller than on four-wheeled vehicles, making the process more challenging. Two-wheeled parts are also aerodynamically shaped and have complex 3D profiles. To meet these requirements, Dürr offers DXQ3D on site, a software that determines the optimal painting path for each part. Additional monitoring software further enhances process efficiency and sustainability.

A demanding market

In India in particular, Dürr faces many competitors who offer paint systems at lower costs and with shorter delivery times. “We try to win the industry over with quality and customized concepts – many customers are willing to wait a few weeks longer for their customized and modular solutions,” says Prashanth Alevoor, Managing Director Dürr India. This approach has proven successful. Over the years, Dürr has established itself as a leading paint shop manufacturer for renowned Indian motorcycle and scooter manufacturers. Dürr India also supports the local economy by setting industry standards and contributing to the growth of electric vehicle (EV) production in the two-wheeler sector. The company has successfully completed its first projects in the electric vehicle field. “Ola’s EV two-wheeler project opens doors for collaborations with other leading EV manufacturers like Ather and Hero.”, explains Alevoor. And what about sustainability?

“This is becoming increasingly important to customers. However, the adoption of sustainable technologies is still progressing slowly in some countries,” adds Alevoor. Many two- and three-wheel manufacturers still use wet separation. EcoDry X, with its disposable cardboard filters that absorb the paint, represents a significant step toward greater sustainability in the painting process.

Other topics will also occupy the Center of Excellence in the coming years. "We want to show customers the advantages of automated painting processes and continue to impress them with our technical innovations. The topic of digitalization will also influence production. We are also committed to more localization," explains Alevoor. This means that nothing stands in the way of achieving the ambitious goal of establishing ourselves as the preferred supplier of paint systems for the two- and three-wheeler industry worldwide.

You can find out more about painting two-wheelers in our brochure.