Reaching for the sky

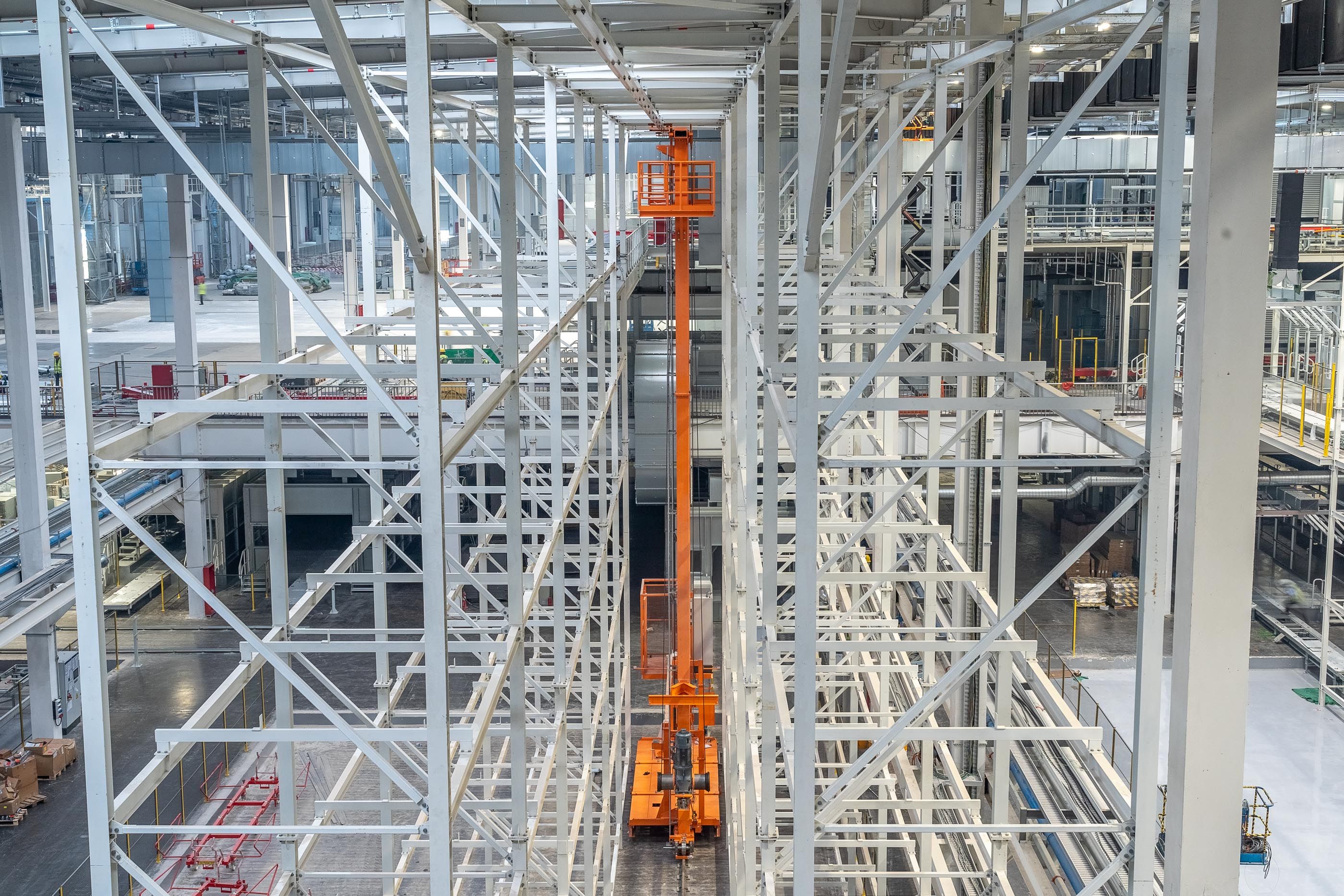

In the high-bay storage, we store vehicle bodies in such a way that they can be retrieved at any time with precise timing – regardless of the order in which they arrived.

Christoph Haist

Senior Manager of Paint Shop Planning at Dürr

Regardless of short-term or long-term storage need, a high-bay storage designed by Dürr is the central hub between application areas in the painting process. For example, it stores car bodies when a spray booth is being cleaned or an oven breaks down. This allows entire lines to be emptied without bringing the entire production flow to a standstill. As a buffer storage, the high-bay warehouse compensates for cycle time differences and allows car bodies to be re-sorted. The high-bay storage incorporates the lift function enabling a higher density of storage through multiple levels. Even outside the paint shop, high-bay storages decouple the material flow and make car bodies available for ’just in time’ final assembly.

Virtually no capacity limits

The operating mechanisms glide along fixed rails in the narrow aisle between the two shelving walls, lifting the car bodies into and out of the compartments. High-bay storages operate most efficiently with a capacity about 40 storage locations. However, there is virtually no limit to capacity thanks to the expansion of rack aisles, including rack-fed storage and retrieval machines. The only decisive factor is how the required cycle time can be achieved.

Scalability and flexibility are key requirements for the paint shop of the future. With this concept, Dürr is breaking with the traditional line layout by distributing automotive painting across boxes. This is where the high-bay storage really shines, as planning for distributed automative painting requires more than just mechanics.

The intelligence of the system lies in the DXQlogistics.control software. It consists of various modules that can be adapted and expanded to meet the individual requirements of a customer manufacturing process. For example, the digital solution helps to efficiently control complex material flows without interruption for different workpiece types, even under constantly changing conditions, with as little effort as possible.

The software also provides answers to important questions that arise in everyday production: How long does a work order take to complete in certain areas? And how can I use rule-based decisions to ensure the optimal retrieval sequence? Intelligent control makes the high-bay storage an active part of a smooth production process. Three functions are particularly central to the operation of a paint shop of the future:

Sequence optimization: The DXQ software groups, for example, car bodies that are to be painted in the same color. This reduces color changes, saves resources, and increases line efficiency.

Flexibility: The software is highly adaptable and supports different storage layouts and individual rules for storage and retrieval.

Process stability: Manual interventions become almost unnecessary thanks to the automated control of the complex material flow. This reduces the susceptibility to errors and thus the risk of unplanned downtime.

From the foundation to the software

Location plays an important role in planning. Within a paint shop, the high-bay warehouse is integrated into the existing building structure. When outside, silo construction is the ideal solution. The roof and walls are attached directly to the high-bay storage, eliminating the need for a concrete building and significantly reducing construction costs. As production grows, the system can be easily expanded without extensive renovations. Every high-bay storage requires a stable foundation for the control unit and the racking structure. Once the racking is installed, the control unit, electrical system, and software integration follow. Many assemblies, including the electrical pre-installation, are already pre-assembled during production at Dürr.

With our experience from several dozen high-bay storages installed worldwide and a wide variety of logistical and mechanical requirements, we ensure that every system runs smoothly – from the first screw to the integration of our DXQ software.

Christoph Haist

Senior Manager of Paint Shop Planning at Dürr

The high-bay storage scores highly in terms of safety and maintenance. While surface storage systems require numerous safety components such as fences, doors, and switches, the high-bay storage requires significantly fewer – and is still just as safe and reliable. Maintenance is also easier: instead of around 60 motors on the roller conveyors of a conventional surface storage system, only three motors control the storage and retrieval machine. The storage compartments can also be conveniently maintained from a passenger cabin on the control unit. This significantly reduces maintenance effort in the high-bay storage and has a positive effect on the high availability of the system.

Looking at the big picture, it becomes clear that high-bay storages are more than just storage space. They are dynamic hubs in production. With precise control, flexible adaptability, and minimal maintenance requirements, they take painting processes to a new level of efficiency. For manufacturers who rely on intelligent storage solutions today, Dürr’s high-bay storge not only creates space, but also increases speed and reliability for tomorrow's production.