No day is like the other

8 a.m. Roland Schipietz sips his coffee in his office in Bietigheim-Bissingen. This quiet moment at his desk is the exception rather than the rule, because as a member of the technical sales team, he spends a lot of time on the assembly floors at the company's headquarters in Germany, at the test center in Ledec, Czech Republic, or anywhere else in the world where the industrial customers' machines are located. “No day is like any other – and plans often change very quickly,” Schipietz confirms with a smile. “If a special situation suddenly arises at a customer's site that cannot be assessed or resolved remotely, I'm in the car or on a plane the next morning. The meeting with friends planned for the evening will just have to wait.”

Technician, mediator, problem solver

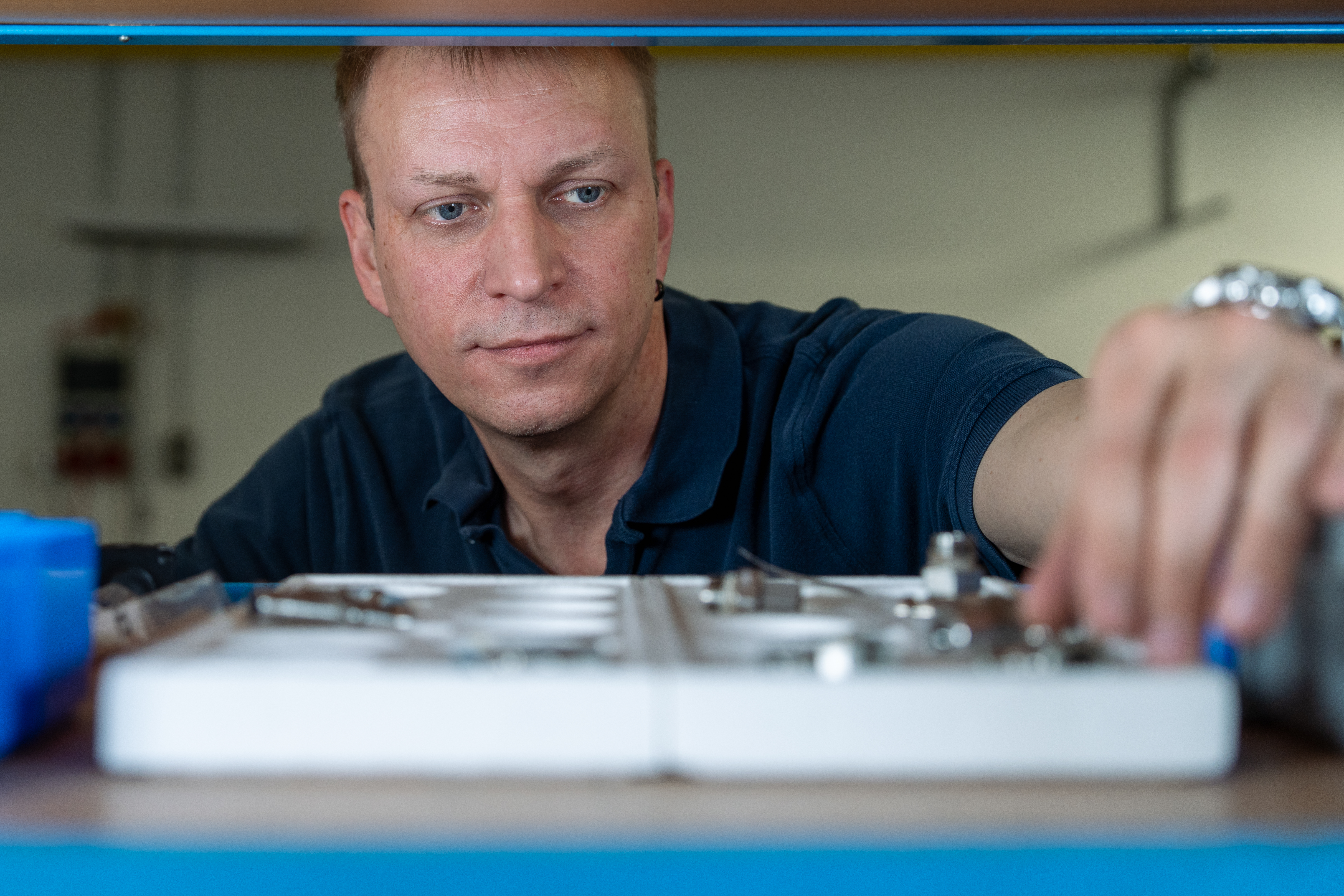

Roland Schipietz's tasks do not fit into any pattern. That's exactly what he likes about his job, because it brings him into contact with people from a wide variety of fields. He supports his sales colleagues with technical queries, sets up test rigs, or carries out coating tests himself – documenting, analyzing, and passing on the results. If he notices any deviations, he consults with quality assurance and feeds his findings back into product management. He conducts hands-on training with customers on site or via Teams and works with them to find solutions. These intensive insights into practice make him the ideal interface between the development department and the INP sales team.

Creativity meets technical expertise

“Typically, nothing is typical,” reports Schipietz as he leans back and relaxes. “Our customers come from a wide variety of industries, so every request is different.” If there is such a thing as a common thread, it is rough process ideas with a request to check whether such a painting process could even work—in the desired cycle time? And with which equipment? Schipietz draws on a wealth of experience to make a well-founded assessment. “It doesn't feel like it, but I've been in the industry for almost 28 years. During that time, I've seen, tried, and learned a lot – especially from what didn't work,” he says, looking back and greeting a passing colleague with a friendly nod.

Direct contact with other experts is important to him for sharing knowledge and understanding contexts. “A quick chat often helps more than hours of brooding alone,” he says. This is especially true when it comes to new painting processes – such as the optimal web overlap for robots or the right parameters for new materials. After all, the better the assessment in advance, the smoother things will run later in the factory.

Support across time zones and on site

The coffee is empty, and the peace and quiet is over. As soon as the laptop boots up, the first emails pop up – many of them arrived during the night. One of them contains only a photo and a brief description: The control system is showing a high-voltage error. Schipietz knows immediately that this cannot be resolved by email.

Considering the different time zones, he doesn't hesitate for long and starts a video call with the customer. Sharing screens, asking questions, clarifying details – direct communication is often the fastest way.

A problem can’t be solved faster than when the phone rings. Another customer reports a serious issue: an atomizer is no longer working because the air motor has been flooded with rinsing agent. “He can't explain it and is asking for help because he uses his own control system,” Schipietz summarizes the conversation as he closes his laptop. He sets off immediately, as the customer is not far away. Together with the operator on site, he carries out several tests until the cause is finally identified in the control system. “The atomizer was already defective, but after replacing it, this can´t happen again,” Schipietz summarizes the result after returning to the office a short time later.

Painting unusual objects

He quickly scrolls through countless emails, followed by more phone calls – nothing out of the ordinary. But even after almost three decades in the industry, there are still requests that surprise him. “One of the most unusual was for the automated painting of coffins. I'll probably always remember that because it was so unexpected,” says Schipietz with a smile. He carried out an offline investigation, simulated path courses, and checked the feasibility.

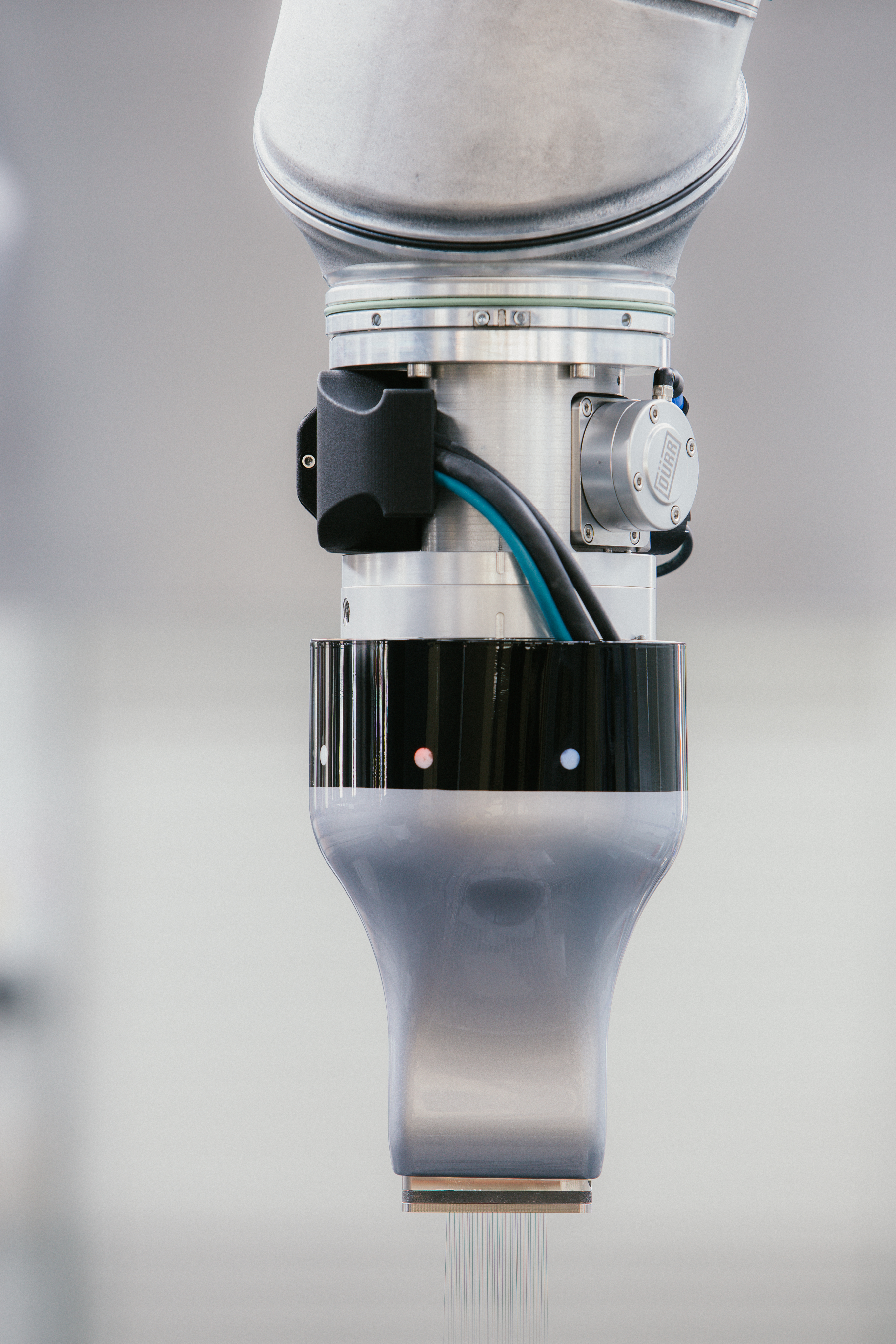

Even though the project was not realized in the end, the effort was not in vain. Shortly afterwards, an integrator implemented a similar project, which now sees urns coated in series using Dürr's Ready2Spray robot.

As unusual as some requests may be, there are projects that make even an experienced technical specialist like Schipietz beam with pride. His personal highlight? The development and commissioning of a coating process using the EcoPaintJet for overspray-free painting of glass plates. “It was technically challenging. There were a few hurdles along the way, but when you see thousands of these glass plates being painted using the process we developed, and the customer is really satisfied – that's a real sense of achievement.”

Today glass, tomorrow wood, the day after tomorrow plastic or metal; sometimes as a precise line without spray mist, sometimes as a large-area, even coating. “Routine? That doesn't really exist for us, and that's a good thing. Because variety challenges us in the best possible way, as each new task brings new technical solutions and our skills grow,” says Schipietz.

For today, he shuts down his laptop and looks forward to the challenges that await him tomorrow.