New level: Dürr’s SCADA system

Until recently, all SCADA systems had a monolithic structure and were designed as largely isolated stand-alone solutions. As a result, communication between different levels or services at the same level was not possible. The monolithic structure also had disadvantages in terms of maintenance and updatability.

Dürr is the first provider on the market to have developed a modular SCADA software solution, i.e. one based on microservices, to market maturity

Marco Hornung

Product Manager DXQ at Dürr Systems AG

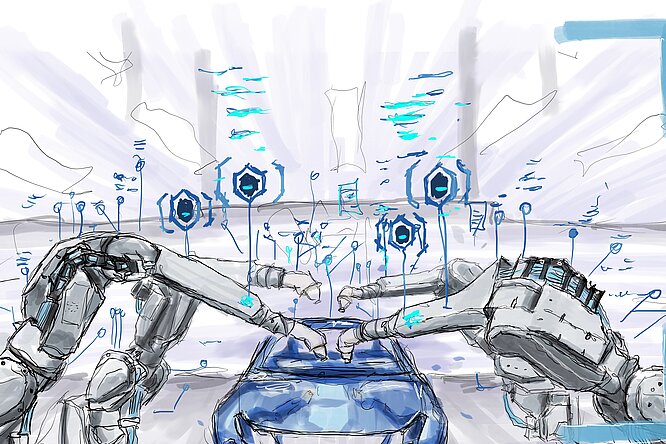

More than 50 microservices work independently but in coordination with each other and are in open communication. The microservices architecture of DXQcontrol is based on the principle of containerization and has open interfaces. “Now we can respond even better to customer requests and our customers have the option of integrating self-developed services into the software landscape,” states Marco. They can be flexibly installed on IIoT platforms in the cloud, on-premises or in hybrid scenarios in the factory. Generally speaking, additional microservices are easy to deploy as needed. This means that customers can map additional use cases at any time by integrating further microservices. However, only those that are actually needed are installed to ensure efficient resource allocation.

Data transparency makes system use interesting for many areas

Thanks to the new architecture, the boundaries between IT and OT are eliminated and seamless communication between the different automation levels is ensured. As a result, DXQcontrol provides a high level of data transparency, which opens up the application to a range of industries, particularly discrete manufacturing. The use of the latest technology components makes it easier to customize dashboards and enables not only process-oriented but also plant-oriented views.

Further development to Manufacturing Operations Management (MOM)

In recent years, Dürr has worked intensively with its subsidiary iTAC to expand DXQcontrol into a Manufacturing Operations Management (MOM). The process-oriented MES from iTAC combined perfectly with the plant-oriented SCADA solution from Dürr. “The state-of-the-art software is a versatile solution that covers every facet of manufacturing, from planning and execution to control, monitoring, optimization and predictive analysis,” explains Marco. This collaboration has given Dürr a technological advantage.

The MOM system is so far unique on the market and has already been sold to several customers.