Modularity as the key to efficiency

What are the biggest changes you are currently seeing in vehicle production, and why should companies act now?

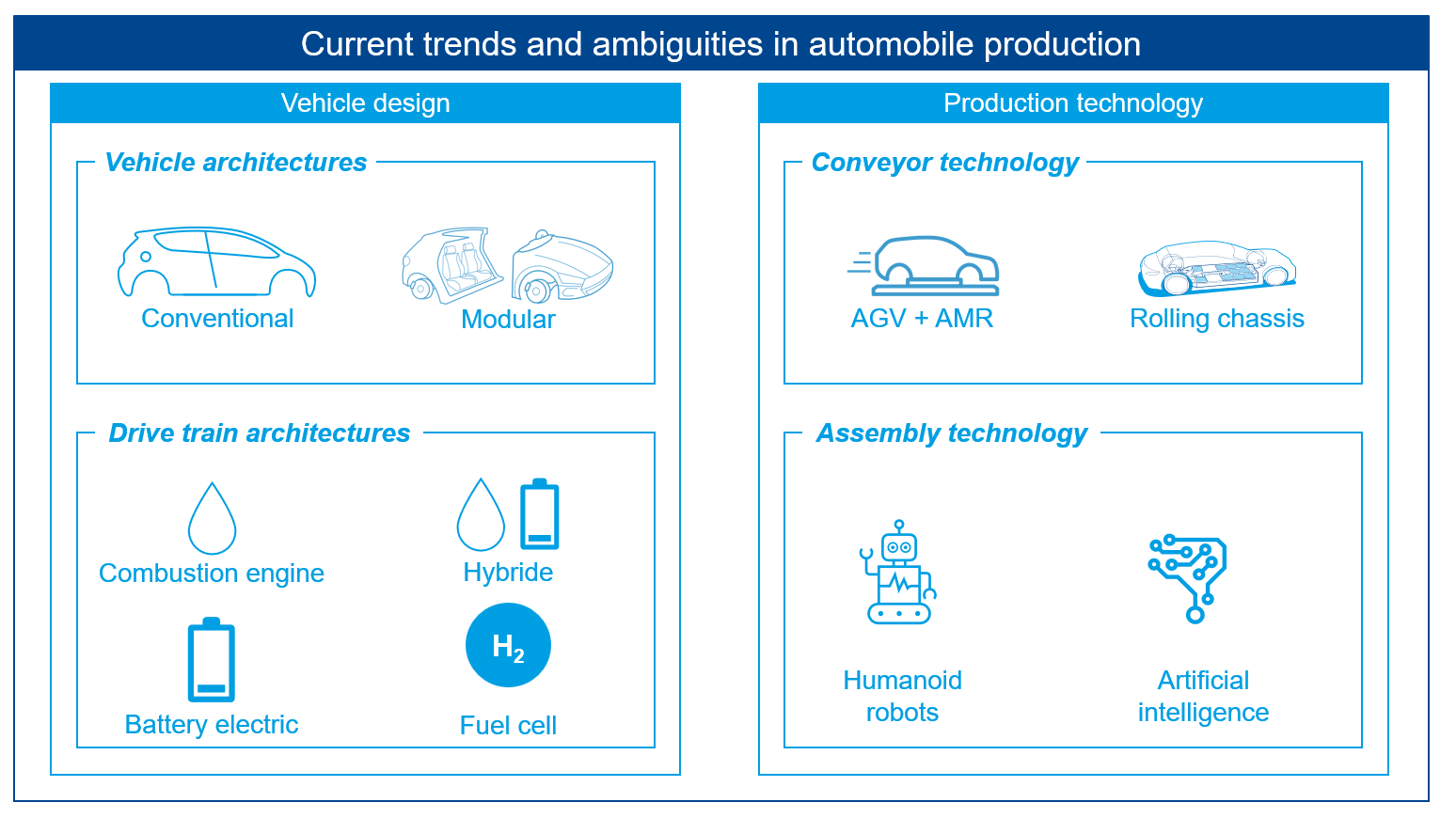

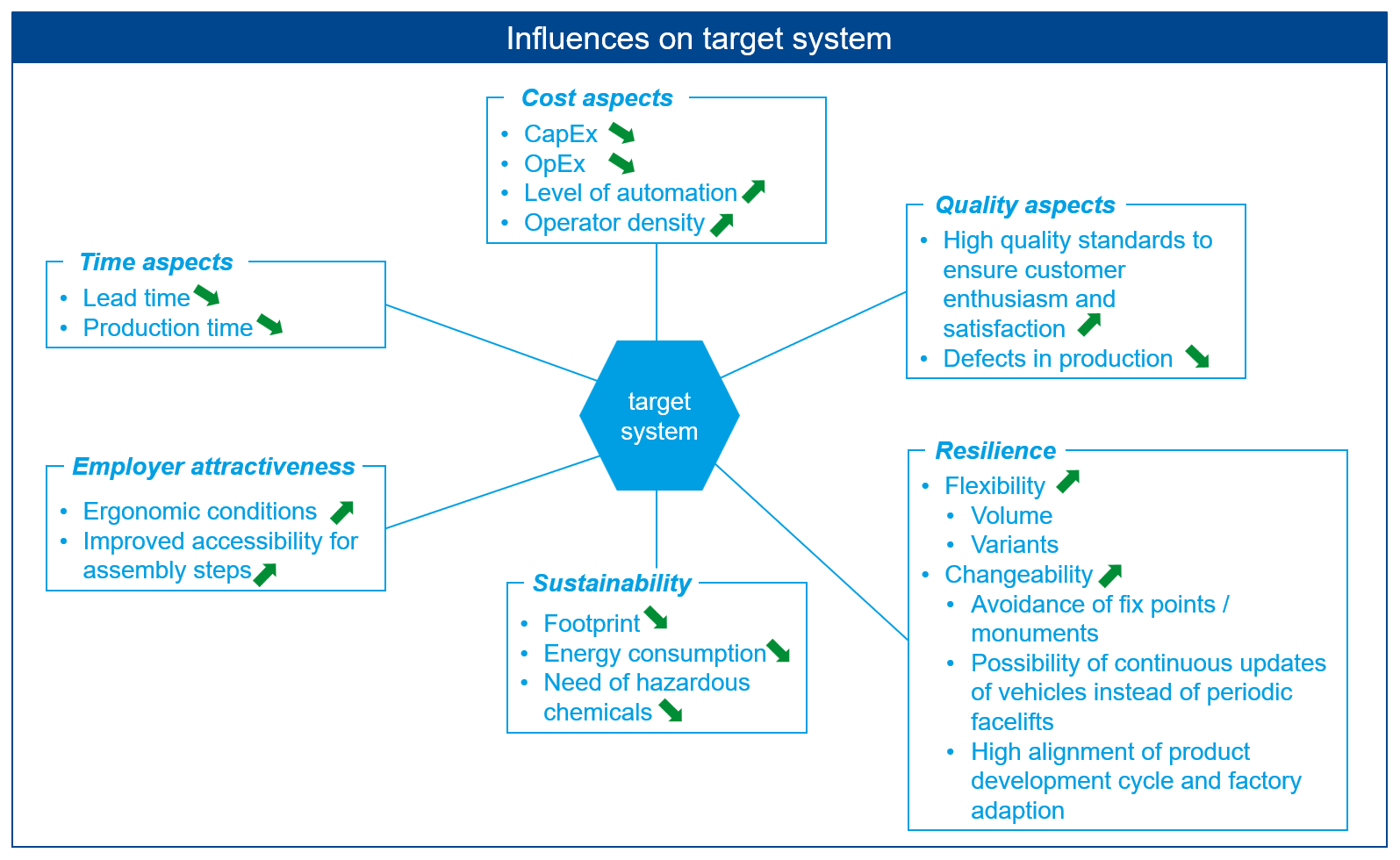

Automotive production is undergoing a significant transformation. One major driver is the intense cost pressure manufacturers face to remain competitive. At the same time, global competition is noticeably increasing. Companies are facing a high degree of uncertainty – such as fluctuating unit volumes and expanding product variants. Today's production landscape is characterized by enormous variety, which greatly increases complexity. These challenges are forcing companies to find new solutions.

For many years, little has fundamentally changed in production systems and the products. Both areas offer opportunities to reduce costs and ensure competitiveness. Companies that act today are actively adapting to change and securing their own future.

What role do modular vehicle architectures play in the future of automotive production?

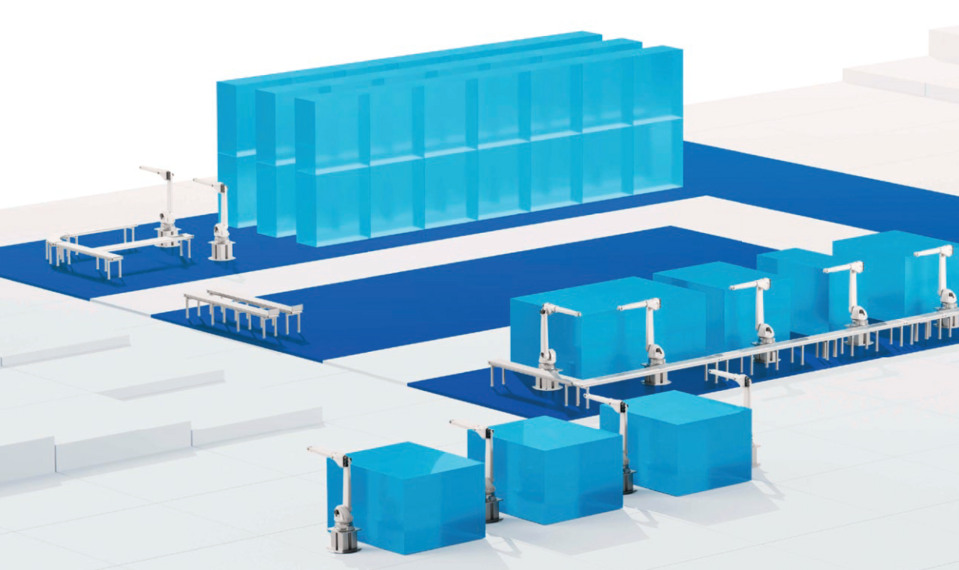

Modular vehicle architectures are a key enabler in fundamentally improving vehicles and making production more efficient. In addition to the necessary adjustments to the production system, modularity offers a strong opportunity to reduce costs and increase productivity. This is a disruptive approach that almost all OEMs, as well as many startups, are currently evaluating intensively. There are high hopes that modular concepts are seen as a pathway to significant leaps in efficiency and cost reductions.

How does Dürr Consulting's production strategy assessment help you maintain an overview and make the right decisions?

Our production strategy assessment offers companies a structured and methodical approach to gaining clarity. Together with our clients, we identify the key levers for the respective company and determine which strategy best aligns with their individual situation, goals, and framework conditions. This provides orientation in a complex environment. In this way, we help our customers make informed decisions and position themselves for long-term competitiveness.

What is your most important advice for companies that want to prepare for new vehicle concepts and technologies?

Our most important advice is to actively observe new vehicle concepts and technologies and remain open to their potential. It is worth engaging with these trends because they offer real opportunities to position yourself for the future. Innovation should not be pursued for its own sake. Instead, it should support clear goals, such as reducing costs. Technologies are tools that should be applied in a targeted manner – always with a focus on delivering benefits to the company.

What makes Dürr Consulting the ideal partner to support companies in optimizing their production strategy in times of change?

Dürr Consulting brings many years of experience, sound benchmarks, and a team that combines strategic, methodological, and technical expertise. Our long-standing partnerships demonstrate the trust that customers place in our work. Driven by a passion for innovation, we support companies make their production systems flexible, efficient, and future-proof.

What are the biggest challenges when it comes to adapting your own production strategy to rapidly changing market requirements?

The biggest challenge is finding a solution precisely tailored to the company’s individual conditions and goals. There is no “one-size-fits-all” approach. Flexibility and adaptability are crucial factors – they must be considered and built into the strategy from the beginning to survive in a volatile environment.

In your opinion, which current trends in the automotive industry are the most important for remaining competitive in the long term?

It is important to have product designs that make production more efficient and reduce costs, for example by applying modularity and standardization.

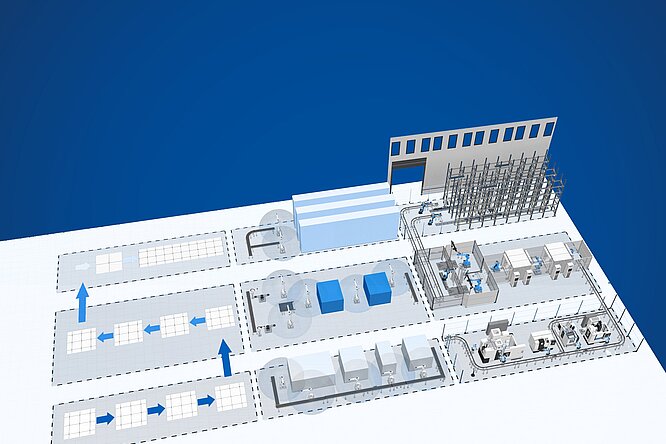

At the same time, production systems must become more flexible and adaptable, as traditional line concepts often reach their limits. Automation plays a central role, especially in high-wage locations, to maintain both costs and product quality. Digitalization is also crucial—but only once stable processes are in place. Optimized processes further improve meaningful data analysis and support continuous improvement.

Discover our White Paper and stay one step ahead!