Industrial products on course

Mr. Tautz, how big is the INP team?

We currently have 40 colleagues across 18 countries – so it's a very international team. Despite the distance, we stay closely connected. We meet virtually regularly and in person twice a year. We discuss the latest technical developments, and which solutions have been particularly well received by customers.

Which industries does INP serve and what does the abbreviation stand for?

At Dürr, “Industrial Products” (INP) refers to everything that is coated in various industries but has nothing to do with painting car bodies. It's an incredibly broad field. To be honest, there's hardly anything that isn't coated with our application products.

It ranges from small Easter eggs to huge components such as aircraft wings. Sometimes it's simple protective coatings for gas cylinders, other times extremely high-quality, high-gloss surfaces for musical instruments. It's this diversity that makes the work so exciting.

From the automotive industry to entirely new sectors – how did Dürr come to establish this division ten years ago?

We are true specialists in paint systems for the automotive industry. We wanted to make this expertise available to other industries. Our products have proven themselves on the market for many years and can be used in a wide range of painting processes. Founding INP a decade ago was the right decision – it has grown steadily since then, and automation continues to offer great potential.

Many companies are currently facing the challenge of broadening their base. How has Dürr addressed this in terms of personnel at INP?

From the outset, we naturally brought several colleagues from our automotive division on board, but we also specifically recruited people with expertise from other industries.

Today, our product managers and technicians work closely with the automotive development department. This direct line of communication is extremely valuable because we inspire each other and can respond quickly to new requirements.

Do you have an example of what this cross-departmental collaboration has achieved?

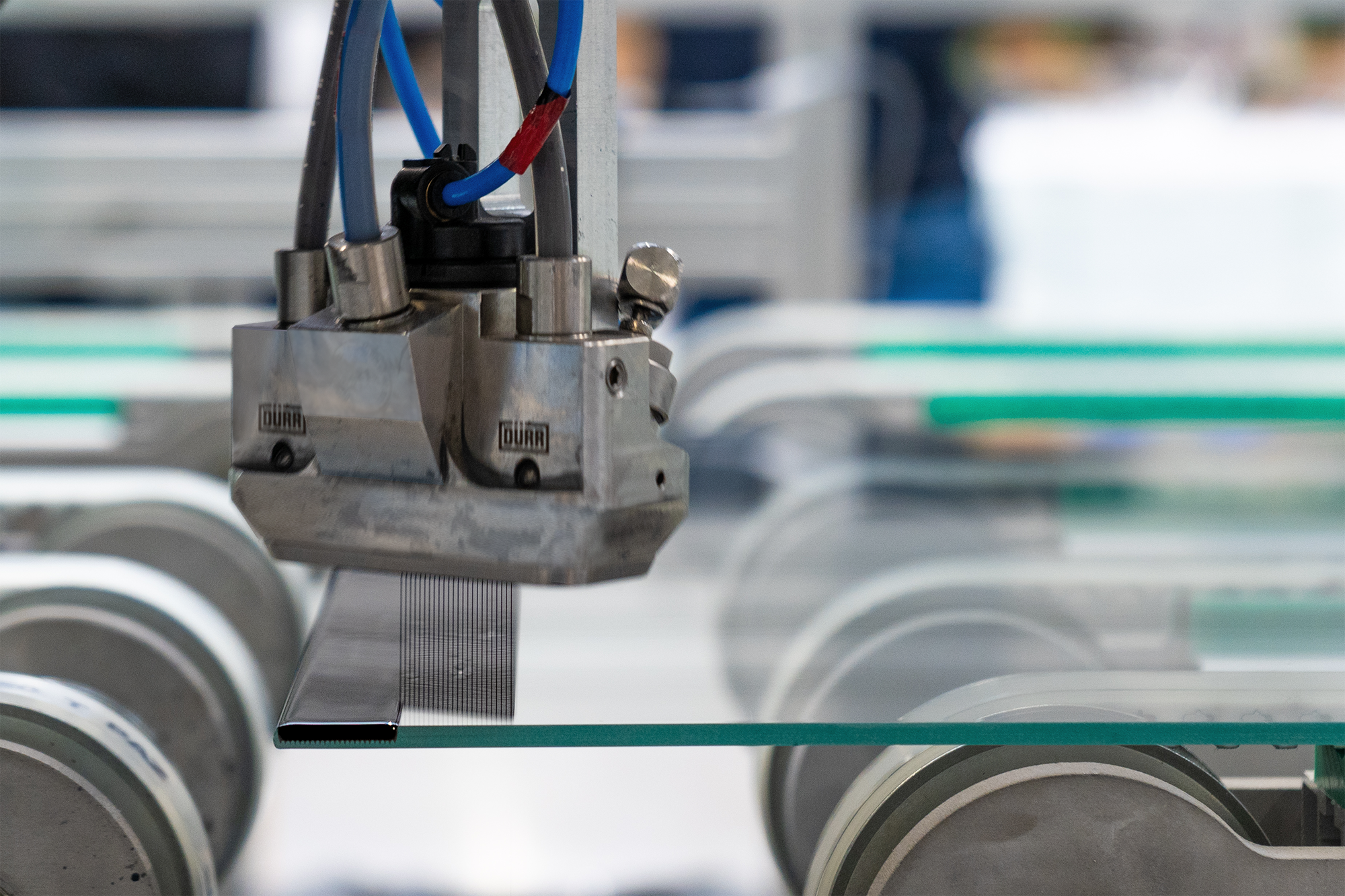

Our highlight, the EcoPaintJet application system, is a good example. It has been running outside the automotive industry for over a year now at PAN-DUR, a manufacturer of insulating glass for commercial refrigeration units – those large, refrigerated display cases and counters from supermarkets. To prevent the adhesive and sealing joints from being visible, opaque decorative strips are painted on. With the EcoPaintJet, PAN-DUR saves time, paint, and space because the system paints with sharp edges and without overspray. Since the paint goes exactly where it belongs, the complex screen-printing process has been completely replaced.

A series line sounds like a big step toward automation. Don't many companies that still paint manually start with smaller solutions?

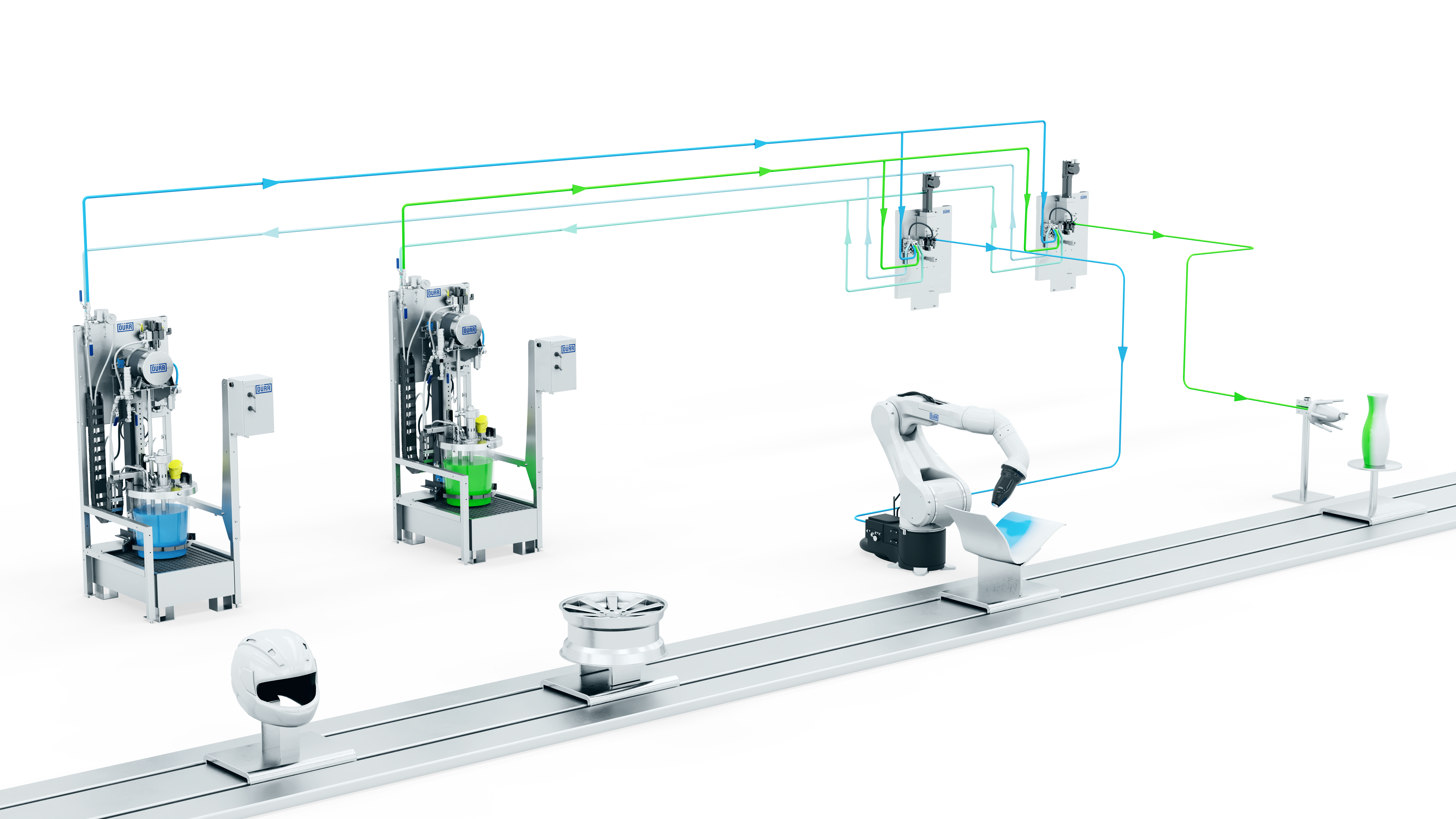

That's right, which is why we developed the core variants based on our ready2integrate concept. Dürr has long pursued the goal of seamlessly combining individual products – from the control system to the applicator – into a high-quality coating solution. The components are preconfigured for specific coating tasks and can be put together as ready2integrate sets as needed. This allows many companies, even smaller ones, to obtain exactly the automation they need for their painting process.

And does sustainability also play a role?

This is especially relevant for small and medium-sized companies that use up to four robots. They not only want to manufacture more efficiently but also save paint and solvents. Automation and sustainability clearly go hand in hand.

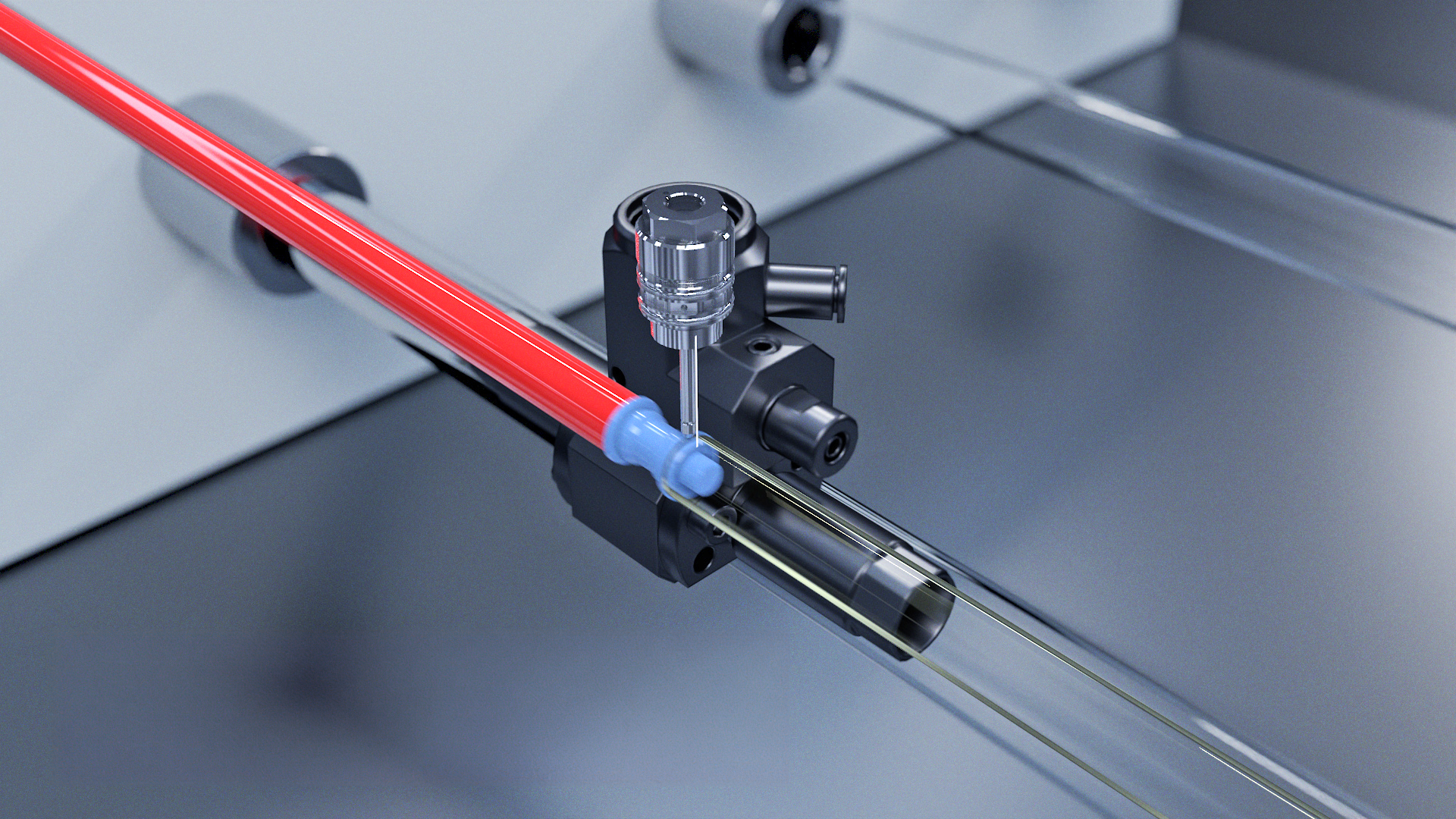

One example is the EcoSupply P Core – a paint supply system with pigging technology that recovers almost all unused paint, minimizes the consumption of detergent, and speeds up color changes. The Core version is ideal for applications where different paint colors are processed in small quantities, such as in the woodworking or construction industries.

What other drivers are there for automation?

I often hear that there’s a shortage of painters worldwide who can consistently deliver high quality. Automated processes are needed to meet market requirements. At the same time, product and color diversity is increasing. Suppliers, for example in the construction and plastics industries, must use more colors to meet the individual preferences of their customers. To become more flexible, they need automated systems for quick color changes. In other words, INP's customers want high-quality, intelligent products so they can paint better and more efficiently.

That sounds challenging. What skills do your employees need to meet these demands?

Our end customers and integrators are absolute experts in their fields. That's why one thing is crucial for my team: deep technical know-how and a thorough understanding of coating processes. That's the only way we can develop the best solutions.

What personal qualities do you bring to your role?

I enjoy traveling the world – whether with our sales teams, at trade fairs, or directly with our integrators at customer sites. I am a good listener. That's important for understanding what is really needed. Patience and flexibility are also essential, because every industry and every customer have their own requirements.

Looking ahead, where do you see INP in ten years?

First, we take pride in what we have built up over the past ten years! Many of the team have been with us from the beginning, and it's great to see how successful our solutions have become for our customers. That motivates us immensely. We have a clear vision for the next ten years: we want to continue growing and have several strategic approaches to achieve this.