From automotive production to battery cells

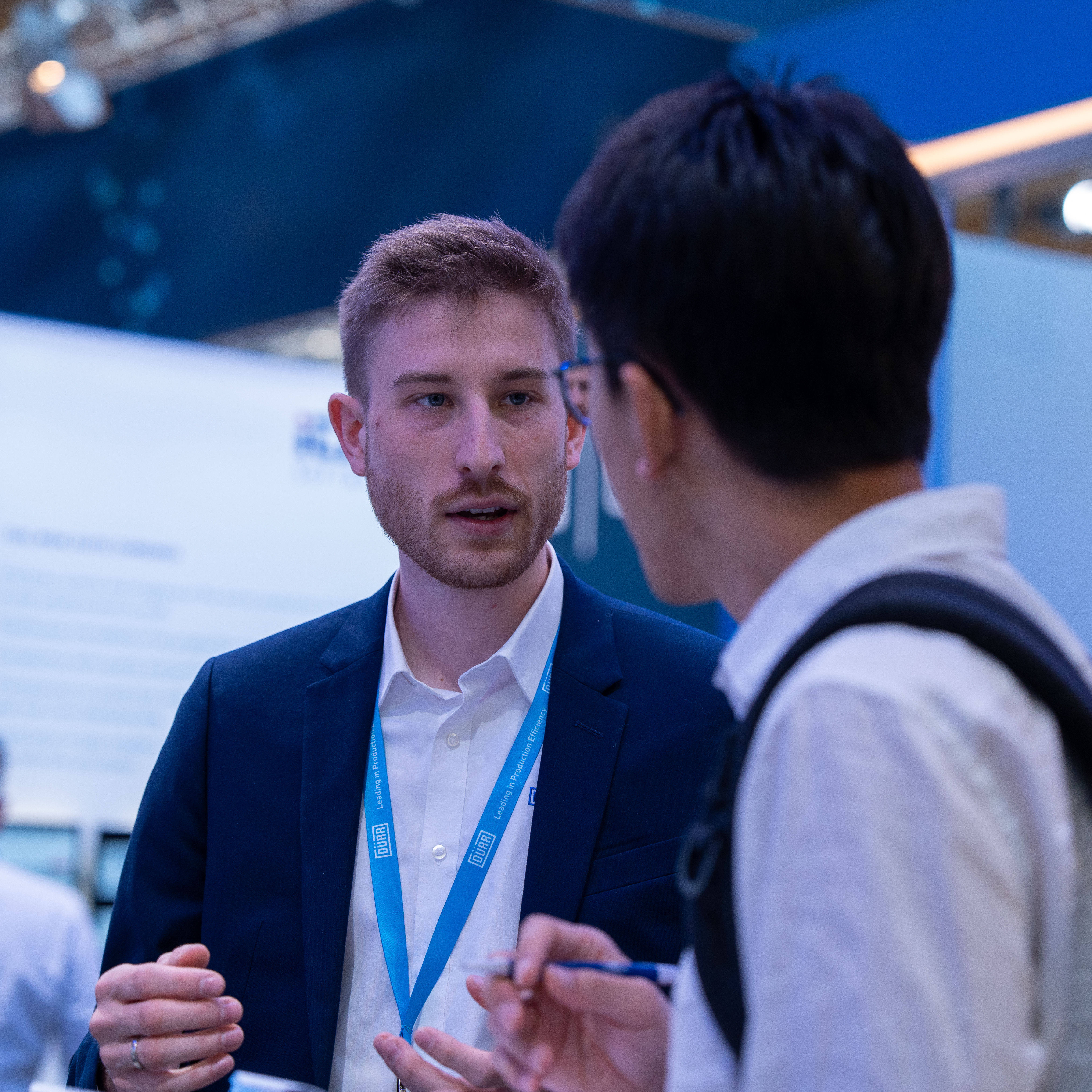

What does Dürr Somac normally fill in automotive production, and how did the connection to battery cells come about?

Bastian: Our systems are used to fill vehicle systems for ABS brakes, radiators, air conditioning systems, engines, transmissions, clutches, and power steering systems accurately and safely with operating fluids – from simple manual single stations to automated, parallel filling with different liquids and gases. With the advance of electromobility, our automotive customers are increasingly getting involved in battery production and cell manufacturing themselves. They are also applying their requirements to battery production. As an established partner to OEMs, we are very familiar with these standards, norms, and other specifications. This is how this market opened up for us. It was the basis for transferring our core competencies to the new field of electrolyte filling.

Electrolyte filling is part of battery cell production. How does this step integrate into the overall cell manufacturing process?

Carsten: Electrolyte filling with X.Cellify PF takes place in the cell assembly area for prismatic or cylindrical battery cells. The anodes, cathodes, and separators are first stacked or wound here, depending on whether prismatic or cylindrical cells are being produced. Then the resulting assembly – a stack in the case of prismatic cells and a so-called “jelly roll” in the case of cylindrical cells – is enclosed in a hard case, filled with electrolyte from above through a small opening, and then sealed. The electrode assembly is a porous system: after filling, it takes a long time for the electrolyte to completely penetrate the active material. This process step of macroscopic wetting and microscopic soaking is followed by the formation and aging of the cells. The cells are charged and discharged for the first time and then stored in a special way to stabilize their electrochemical performance.

To what extent can the expertise gained from automotive filling technology be applied to cell filling?

Carsten: Cell filling is a vacuum pressure filling process, and that is part of our daily business. We know how systems behave in a vacuum and also how they react to overpressure. In the field of refrigerant filling, we usually work with pressures around 20 bar, and when filling with CO2, the range even extends to 120 bar. Unlike in automotive production, however, the container we fill is not empty. The cell contains the electrode assembly, which consists of extremely tightly packed, very fine, and porous active material.

Another important factor is the handling of the medium used as an electrolyte. It is a very complex mixture of substances: toxic, corrosive, flammable, hygroscopic, and crystallizing. We have the expertise in handling demanding media: fuels, for example, are explosive, brake fluid is hygroscopic, and urea – known as Adblue – crystallizes. We have been filling these liquids for decades, know how to handle them, and are familiar with safety and protection concepts. The challenge with electrolyte filling is dealing with all these properties at the same time.

When did development of X.Cellify PF actually begin?

Bastian: In 2021, we received a customer inquiry for filling battery cells. We visited the customer's production plant to see the filling equipment and the process. Although this inquiry did not result in an order, it was clear to us after the visit that we would do things differently with our experience in the automotive sector. We can optimize the process. That was the impetus for our development.

What starting points did you see, and how do you proceed when entering “uncharted territory”?

Bastian: Cell filling is a vacuum process. However, according to the current state of the art, the cells are not completely degassed before filling. This complicates the filling process. In addition, the cell is filled in several steps, with the pressure being reduced and rebuilt several times. We wanted to do this in one step.

Carsten: We had already developed a procedure that we could use as the basis for the new process. As with the battery cell later on, the aim was to fill a non-pressure-resistant system with high pressure. When transferring this to the battery cell, we looked at the fundamentals of the new medium: How does the electrolyte behave? We used models to investigate the influence of residual gases, the penetration of the active material, etc. Then the hydraulic filling process was developed and finally the machine.

What is the composition of the development team at Dürr Somac?

Carsten: Our core team consists of mechanical and software engineers as well as sales staff. Together, we develop the machine's functions, i.e., hydraulics, pneumatics, mechanics, electrics, and software. The team is supported by the operational department. Bastian accompanies the development process and also acts as the link to the customer.

Given that electrolytes for battery cells are hazardous substances, where did the development work take place?

Carsten: Since the medium is very dangerous, we did not work with it at our site. We conducted our investigations with the electrolyte at external partners' laboratories. At our site in Stollberg, we initially had a small test setup for the first tests with substitutes. Then we built a basic unit and a filling chamber. Over time, we expanded these to be able to fill 4 to 6 prismatic cells or 12 round cells in parallel.

What importance did conducting tests in a real production environment have?

Bastian: New developments cannot be realized without customers as partners. Especially since cell filling is only one sub-process within battery cell production. This means we cannot evaluate the end product, the finished cell, in our test environment. In order to test our process, we needed an unfilled battery cell from a production facility that we could insert into our filling machine. The cell we filled then had to be returned to cell production. Finding a battery cell manufacturer as a development partner for this was a major challenge. We finally found a manufacturer and were able to test how the cell behaves, including in combination with substitute materials that we used at our site.

Carsten: In 2024, we filled real cells with electrolyte for the first time. We returned these cells to production, where they were then finished. It was a huge milestone for us to see a functioning battery with cells that we had filled using our process and our machine.

What happened next, and what is the current status of development?

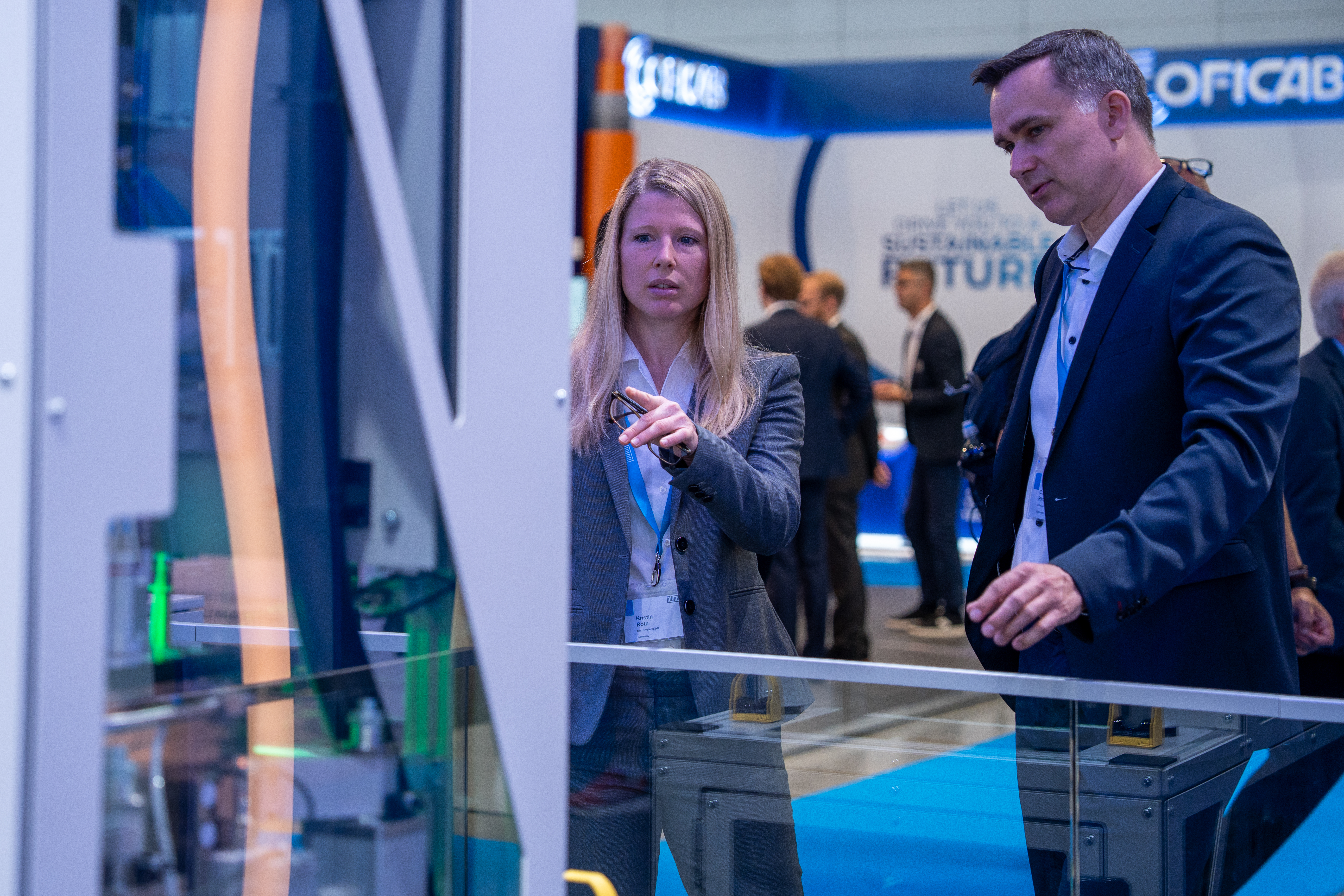

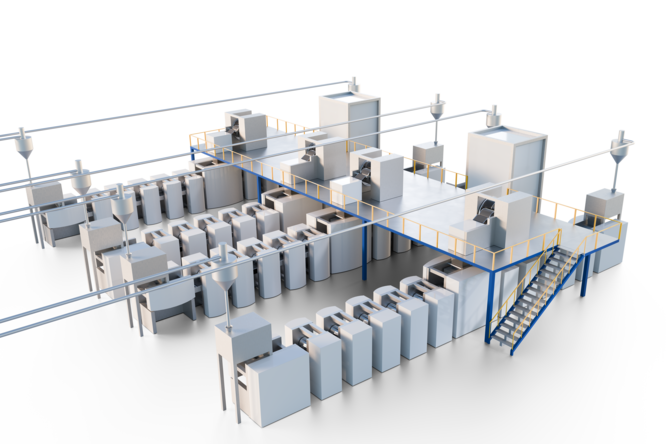

Bastian: Last year, we presented our pilot plant at “The Battery Show Europe” trade fair in Stuttgart, where our technology attracted interest from many customers. Shortly afterwards, we delivered a pilot plant consisting of a control cabinet, base unit, and filling chamber to a customer. We are currently in talks with other customers with a view to further establishing our product in industrial manufacturing.

What is special about the X.Cellify PF electrolyte filling system?

Bastian: In a nutshell: With X.Cellify PF, we fill the cells directly, in a single step and in parallel, using high filling pressure. In conventional cell filling, on the other hand, the electrolyte is filled into the cells from a pre-filled cup system, a kind of storage tank, with nitrogen pressurization.

Our special filling adapters are a crucial component in filling technology for automotive production and a reason for many OEMs to buy. The workers in final assembly use them in a similar way to a fuel nozzle. They contain a lot of mechanical technology, actuators, and sensors. We have incorporated this expertise into the filling heads of X.Cellify PF. They function similarly to filling adapters, except that they are not attached manually but are permanently installed. Our technology allows us to fill quickly at high pressure. With a filling pressure of up to 30 bar, we achieve three times the current industry standard. The high filling pressure is of interest to manufacturers because, on the one hand, we can fill faster and, on the other hand, we also shorten the downstream wetting, i.e., the penetration of the electrolyte, because we achieve a higher wetting rate immediately after filling.

With our high-precision, proprietary dosing system, we also fill with great accuracy. Our process is supported by optimal vacuum performance and a proprietary, gentle electrolyte pretreatment that removes dissolved gases from the electrolyte. In addition, we have our own safety concepts that have been approved by the Technical Inspection Agency (TÜV). We have also placed particular emphasis on the maintainability of the system and durability of the components used. Another relevant factor for cell manufacturers is our modular system design with a reduced footprint.

What types of battery cells can be filled with X.Cellify PF? What role do cell shape and cell chemistry play?

Bastian: We can fill cylindrical and prismatic hardcase cells with a wide variety of cell chemistries. We are seeing a trend toward the use of thicker electrolytes. This makes filling more challenging and highlights the advantages of our high-pressure filling process.

What are the next steps in bringing X.Cellify PF to battery cell factories?

Carsten: Our long-term goal is to further develop X.Cellify PF for series production and use it in gigafactories. In order to scale our machine, we are working with standardization and modularization – just as we do in automotive production. However, implementation can only succeed in collaboration with our customers.