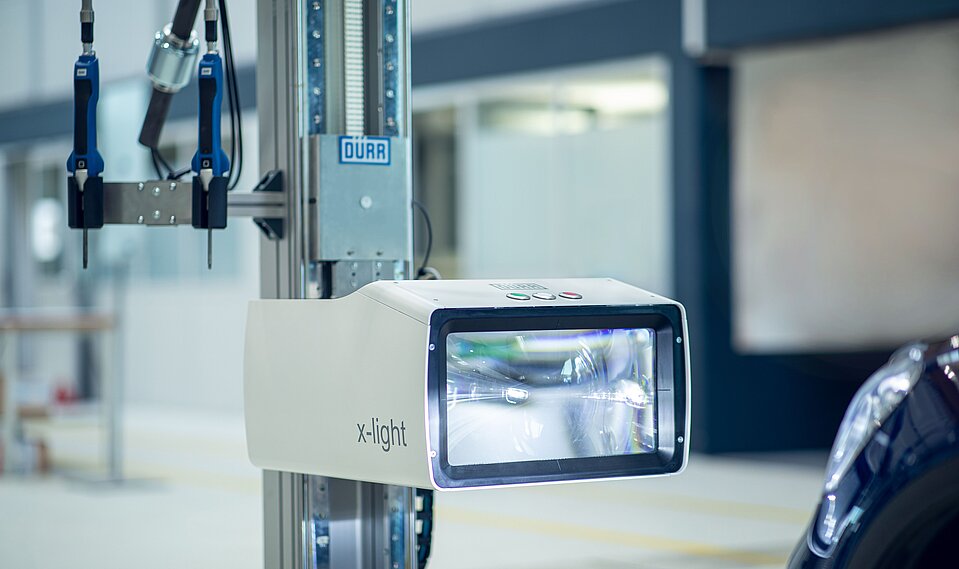

X-light measures wide LED headlamps

Vehicle manufacturers are responsible for setting and testing vehicle headlamps, a legal requirement in all countries. Generally, this happens during end-of-line production and is combined in a single operation with wheel alignment adjustment and measurement on the wheel aligner x-wheel. The symmetry axis, determined by measurement, specifies headlamp alignment and the LED modules fitted in them. As new headlamp generations incorporate an increasing number of LEDs to facilitate custom designs, light measurement requirements have correspondingly grown.

Fresnel lens captures even super-wide headlamps

The x-light’s super-wide Fresnel lens can even capture and measure a light image generated from numerous LED modules. Customers have praised the new x-light for its ability to accommodate wider headlamp designs expected from future LED systems. The x-light is fully equipped to handle these evolving requirements, making it a top choice. Its image analysis software also analyzes different light images from increasingly specific adaptive systems using standard algorithms. Dürr can also integrate special measurement algorithms into the image processing software upon customer request.

Factory calibration guarantees uniform measurement results

In addition to the roughly suitcase-sized light measuring device, the x-light system comprises a supporting gantry with a Z-column, a control cabinet with a control panel, and the semi-automatic adjustment tool Smart Ergo Drive which measures all headlamps on the market, regardless of origin. The x-light system comes with a factory calibration certificate, which guarantees that all light measuring devices are set the same and deliver identical measurement results. An added benefit is that the entire light-measuring device can be replaced quickly and easily in the event of a fault without lengthy production interruptions.

Faster replacement thanks to an adapter

With the help of a quick-change adapter, the compact light-measuring device easily attaches to the Z-column of the supporting gantry system. The predecessor device had a more complicated process for addressing faults: as the camera was bolted to the Z-column, it had to be manually removed and replaced, and the new camera had to be recalibrated and synchronized with other production lines. This was a complex procedure that wasted valuable production time. Dürr recommends keeping a spare light measuring device on hand for fast replacement.

With the help of the gantry system’s interchangeable adapter, the light measuring device can quickly be replaced during production, resulting in less downtime.

Christian Petzinger Product Line Manager x-light & x-DASalign

at Dürr Assembly Products

Low-maintenance light measuring device

The light measuring device’s sturdy aluminum housing virtually guarantees maintenance-free operation, and thus, greater availability. This significantly streamlines device operation and handling. Instead of the previous six control knobs, there are now only three control knobs on the top of the device, which also features a tool tray. In addition, a large window and an engraved projection plate can be operated from the outside, simplifying visual follow-up inspection of the headlamps during test stand setup.

Camera software analyzes IES files

The high-resolution digital camera installed in the device sets measurement accuracy standards, with 0.01 percent deviation or less. In addition, the camera software can analyze light images from newly developed headlamps, even if they are not physically present, by reading the IES (Illuminating Engineering Society) files. This enables production systems for new headlamps to be prepared while the headlamps are still in development.

Software-controlled headlamp adjustment with “Smart Ergo Drive”

After the light image is analyzed, the headlamps can be adjusted either manually with a screwdriver or in a semi-automated process using the electric adjustment tool Smart Ergo Drive. The electric adjustment screwdrivers use software to turn the headlamps in the right direction and stop as soon as they reach the specified setting.

A feature unique to the market: The x-light software has a push-down sensor to prevent false measurement values from the application of excessive force to the headlamps’ adjusting screws. In addition, the Smart Ergo Drive is equipped with LED lighting to improve the view of the adjusting screws in the dark engine compartment area.

Already sold 26 times

Dürr has already sold the new x-light measuring device 26 times to manufacturers in Europe, the USA, and Asia, with the majority used for PVT (Passenger Vehicle Testing). Three x-light measuring systems are in use by CVT customers (Commercial Vehicle Testing) and one in PTI (Periodical Technical Inspection).

Changan purchases complete end-of-line from Dürr

Dürr provided the Chinese manufacturer Changan with state-of-the-art solutions for its complete end-of-line for their new electric car plan in Nanjing. Dürr supplied the x-light headlamp measuring and setting system, the wheel alignment stand x-wheel, and the roll/brake/ABS test stand x-road in the past year.