Technology that saves lives

Ensuring the long-term and reliable functioning of safety-critical ADAS over the entire lifespan of a vehicle poses new challenges for regulatory organizations worldwide. The ViL test stand x-proof 360 marks a decisive step forward in testing ADAS as part of the periodic technical inspection (PTI) of vehicles and sets new standards for road safety. The system, which Dürr has developed in close cooperation with simulation specialist dSPACE, enables the simulation of complex traffic scenarios under controlled, highly realistic conditions and the precise evaluation of the reactions of ADAS.

A partnership for the future of mobility

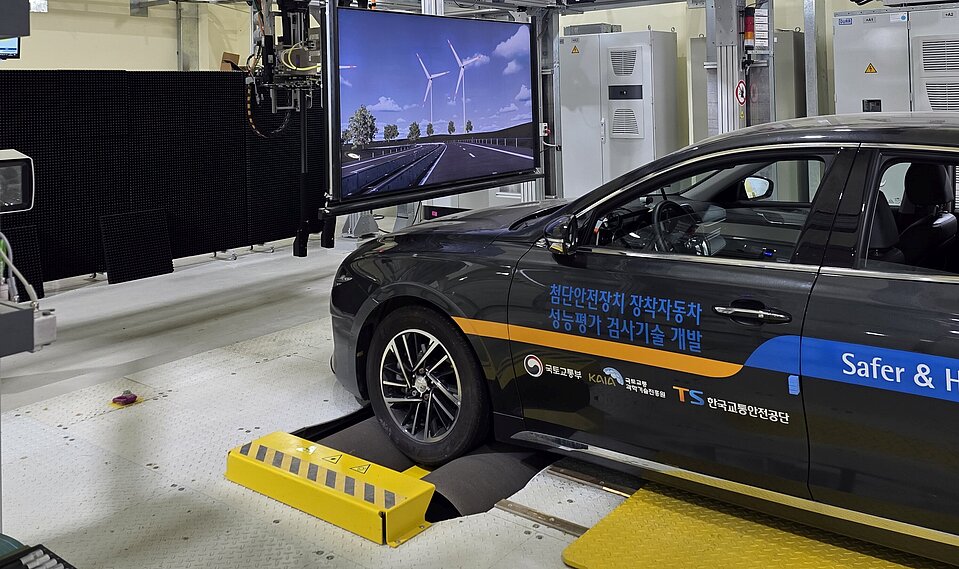

The current presentation builds on an agreement signed in April 2023 between KOTSA, Keyyang, Dürr and dSPACE, which laid the foundation for the development of new, standardized test methods for ADAS. With the test stand now up and running in Gimcheon, the vision has become reality.

Representatives of the partners involved emphasized the importance of this international cooperation during the presentation. “What we see today is more than just a test stand, it is a milestone for proactive safety measures and an important step toward Vision Zero – a future without traffic fatalities,” explained Dr. Jaehwan Jeong, Team Leader of the Advanced Safety Research Department at KOTSA.

A new standard for ADAS testing in periodic technical inspection

KOTSA intends to use the test stand to develop future ADAS test procedures for vehicle inspections in South Korea. With the successful application of the vehicle-in-the-loop method in periodic technical inspection, KOTSA is taking on a global groundbreaking role. The insights gained here will contribute significantly to the development of standardized and reliable test protocols that ensure that driver assistance systems function just as reliably as on the first day, even after years of road use. “The new test stand is a great asset for South Korea and also sends a strong signal to the global road safety community,” summarizes Byungwook Lee, Managing Director of Dürr Korea.

A follow-up project has already been assigned, in which an existing test stand will be used at a Korean test station in Sejong to collect field data with real customer vehicles, which will provide insights into the long-term functionality of ADAS on Korean roads.

In addition, the x-proof 360 allows for the integration of further applications to cover both existing and new inspection test scopes. These include headlight and brake tests, dynamic test cycles for emission measurements, as well as tests for adaptive front-lighting systems, ETC and ABS performance tests.

How are ADAS tested using the vehicle-in-the-loop method?

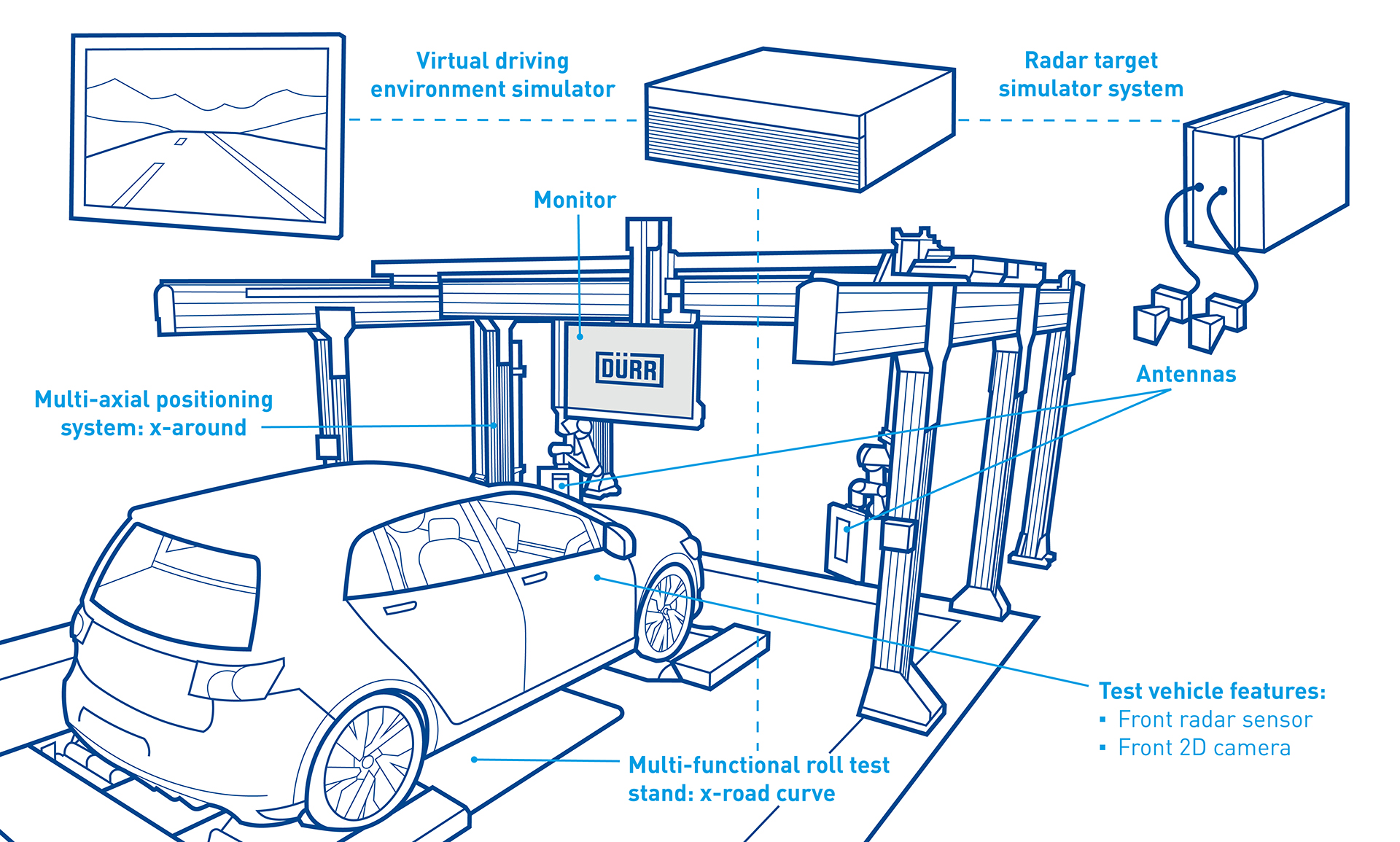

With the x-proof 360 vehicle-in-the-loop test stand, a complete, unmodified vehicle is placed in a virtual traffic environment for ADAS test scenarios in order to simultaneously test the complete chain of sensors, actuators and controllers. The VIL-test stand consists of the patented x-road curve roller test stand, on which the test vehicle can be accelerated, braked and steered, and the multi-axis portal system x-around from Dürr for dynamic positioning of the dSPACE Automotive Radar Target Simulator (DARTS) and a monitor for the vehicle's camera stimulation, visualizing traffic scenarios from dSPACE’s ASM and AURELION.

This creates a reproducible test environment, especially for the camera and radar sensors installed in the test vehicle, to represent a wide variety of test scenarios. These include critical situations such as vehicles ahead suddenly braking or cutting in directly in front of the test vehicle. The test scenarios in x-proof 360 are particularly realistic, as the camera and radar sensors are not tested individually but are stimulated simultaneously to enable sensor data fusion. To successfully complete the test, the vehicle must react reliably to hazards in the VIL simulation and, if necessary, activate the automatic emergency braking or lane departure warning systems, for example.