Pretreatment, simple and compact

1. Mr. Heinsohn, can you start by telling us what EcoProWet is all about?

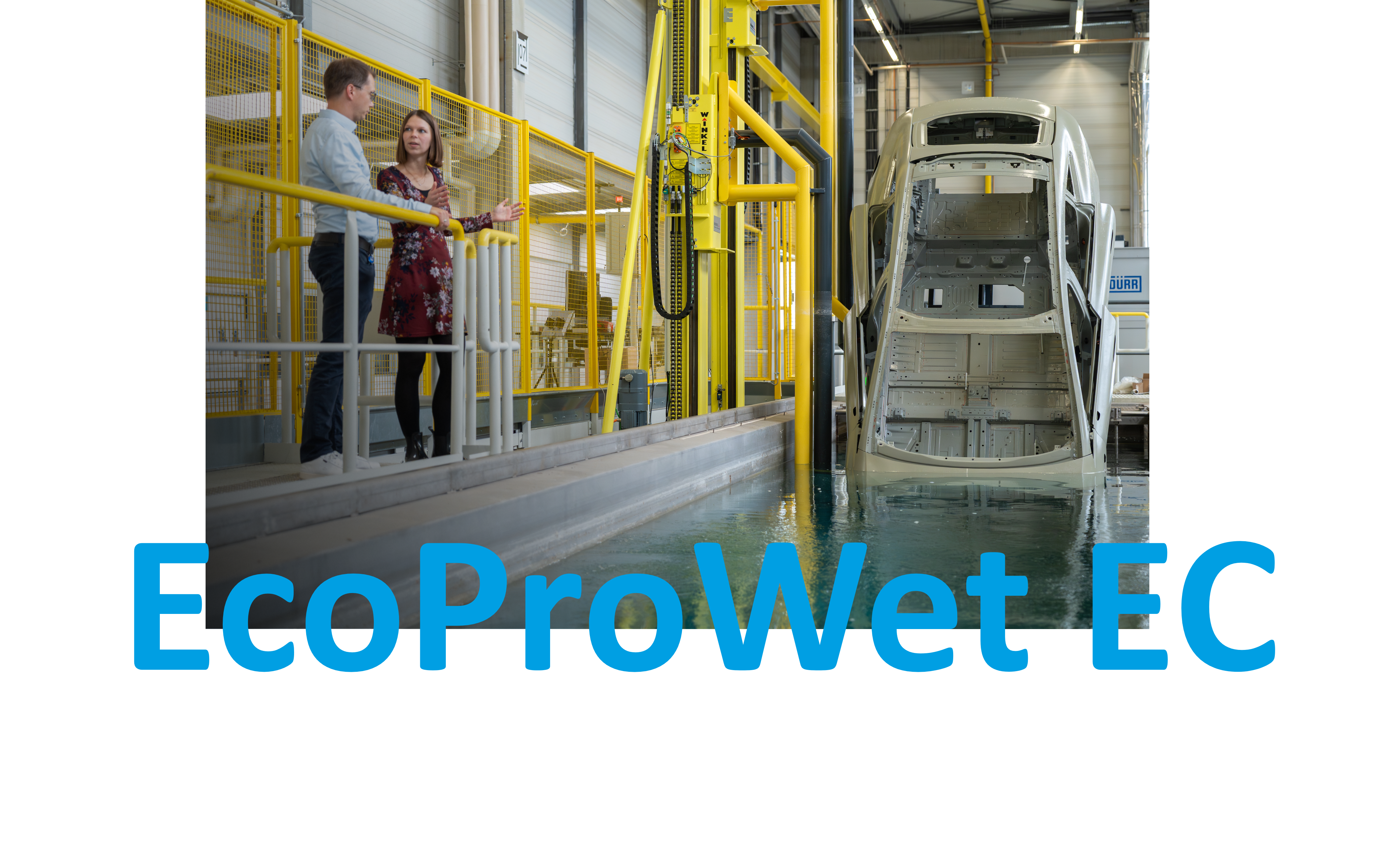

Certainly! EcoProWet is a completely new concept for a modular pretreatment and cathodic electrocoating (EC) system. It can be expanded to match current production capacities and requires very little space in the paint shop.

2. Dr. Seyboth, as one of the developers, can you explain how EcoProWet works in practice?

Yes, of course. At its core, EcoProWet consists of various standardized modules arranged side by side to represent the process sequence. With the help of cross conveyors—typically cross transfer cars with roller conveyors—the bodies are transported from one process chamber to the next.

3. You mentioned the modules. What parts make up the process sequence?

Dr. Seyboth: We basically differentiate between pretreatment and electrocoating. Pretreatment involves electrocoating and spray stages. In traditional systems, the car bodies are immersed in tanks filled with treatment fluids. In contrast, EcoProWet floods the chambers with fluid around the stationary vehicles. In short, instead of submerging the car in liquid, we now bring the liquid to the car in a targeted way. For electrocoating, the process remains largely unchanged, as the special properties of the paint do now allow for a flood method.

4. Can you explain the specific advantages of EcoProWet compared to previous pretreatment methods?

Heinsohn: Both the pretreatment and the electrocoating systems are modular in design and can be expanded as needed. This allows the system to be installed in a very small space while minimizing capital investment. Additionally, EcoProWet offers several other advantages, particularly in terms of energy efficiency, ease of maintenance, quick implementation, and high coating quality.

5. How can PT and EC be combined?

Dr. Seyboth: In principle, EcoProWet PT and EcoProWet EC can be operated independently. If a customer opts for a modular system for pretreatment, they can use cathodic electrocoating with RoDip, for example. However, to fully leverage the benefits of ProWet, it makes sense to adopt the new system.

6. What prompted Dürr to further develop pretreatment?

Heinsohn: The market has been evolving for some time now. In the field of e-mobility, startups are emerging with innovative vehicle concepts in small quantities, aiming to scale up production if successful. This has created a demand for systems that can keep pace with increasing production capacity. EcoProWet is designed to be flexible and scalable to meet that need.

7. And how did you come up with the idea, Dr. Seyboth?

Dr. Seyboth: We didn't just pull the idea out of thin air. It emerged from a structured innovation process moderated by our colleagues in innovation management. Initially, we locked ourselves away with half a dozen experts from the modular pretreatment and cathodic electrocoating department for several workshops and worked on various ideas. This resulted in four potential concepts from multiple angles. After a long process, EcoProWet was finally created.

8. How long did it take to develop and finalize the product?

Dr. Seyboth: Developing such a complex system naturally takes time. Beyond the process-related issues, a concept this innovative required development and clarification in many areas. New solutions had to be found in conveyor technology and control engineering, and questions regarding assembly, logistics, and occupational safety had to be addressed. We mastered all of this through many iterative steps in close cooperation with colleagues from various departments, including process engineering, control engineering, conveyor technology, manufacturing, logistics, and assembly. Above all, we worked intensively with leading chemical suppliers from the industry right from the start. Without their support and joint validation, such a system would never have been successful on the market.

9. When will we see EcoProWet in use for the first time?

Heinsohn: In general, we receive a lot of praise and recognition for our approach and are always involved in projects in detail. It is now becoming apparent that there is interest beyond our “car world” and that we can establish an initial beta site there. We have also installed a pilot plant in our technical center where customers can test the pretreatment of their bodies or other components at any time.