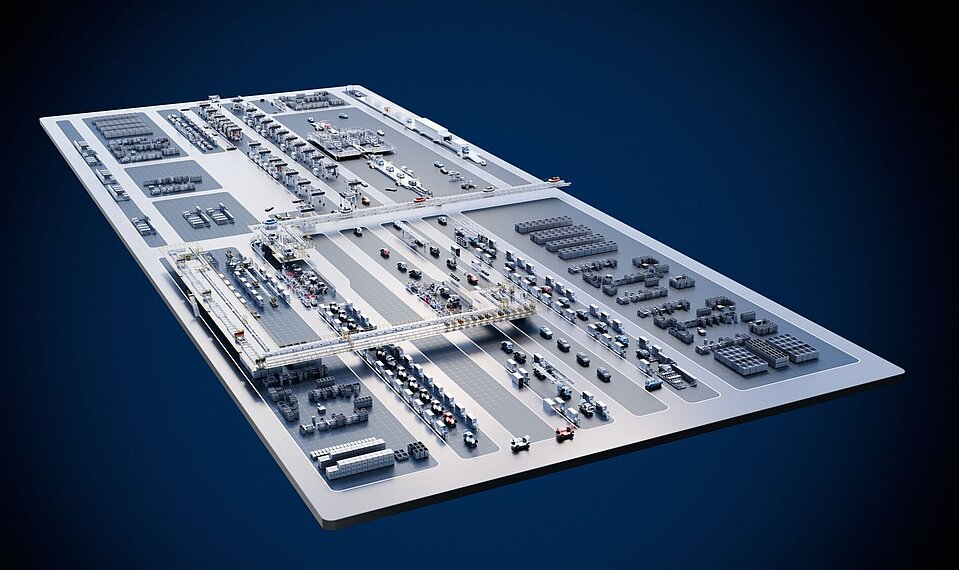

NEXT.assembly of the future

Our focus is on providing world-class logistics concepts, smart customized solutions, and flexible, scalable investments. Whether greenfield projects or brownfield integration, our wide range of digital solutions and innovative technologies will meet your needs. The so-called NEXT.assembly of the future is a layout that by Dürr. It represents the evolution of final assembly over time to overcome industrial, mechanical, and economic challenges.

It is independent of conventional building requirements —no rigid steel structures or complex pits are necessary— and is completely unaffected by the positioning of supporting pillars. The overall concept is designed for modularity and scalability, enabling it to adapt flexibly to production changes such as new models, mixed operations, capacity fluctuations, or new production concepts.

And it’s not only the layout and mechanical systems—our digital backbone is fully embedded into final assembly, ensuring every component, from AGVs to test stands, is part of a seamlessly connected ecosystem. In addition to our state-of-the-art technology, we offer five innovative products that are key to achieving the flexible concept of the NEXT.assembly We call them the “enablers,” consistently interlinked with DXQ, Dürr’s digital intelligence portfolio.

1. DXQ

The enabler spans all areas of final assembly like a network, ensuring interop can be applied in both the paint shop and final assembly, in this context we highlight its use in final assembly.

2. ProFleet

Today, AGVs are indispensable in many production environments—and for good reason. These agile automated guided vehicles can be used individually and flexibly for a wide range of production tasks. These smart helpers are available in a large variety of sizes and ensure efficient intralogistics. That’s why Dürr's ProFleet AGV family is an important enabler for tomorrow’s final assembly. Whether transporting car bodies, heavy components, or materials our high-performance AGVs support almost any application. They can replace or expand fixed conveyor systems, enabling highly flexible and precise production.

All ProFleet AGVs can be precisely tailored to each workpiece and, with optimized travel times and smart control, deliver customized solutions regardless of workload or process. Integrated into the DXQ software environment, they enable real-time tracking, adaptive routing, and predictive diagnostics—making intralogistics and assembly processes both flexible intelligent. With the DXQequipment.maintenance module, operators benefit from user-friendly software that organizes and tracks maintenance task—whether cyclical, dynamic, run-time—ensuring technicians easily monitor upcoming work. AGVs, AGCs and all final assembly can be centrally monitored within DXQequipment.maintenance.

3. ProLiner

Another conveyor system central to NEXT.assembly is the ProLiner—an autonomous guided carrier (AGC). The carrier is nothing less than a revolution in conveyor technology. This innovative system combines features of an overhead conveyor with the advantages of an AGV. ProLiner is a flexible, self-driving hanger system that navigates independently. It is ideal for transporting and lifting heavy loads such as complete car bodies with battery and axle components.

It was specifically designed to maximize flexibility and efficiency in the “marriage” process, where drivetrain and chassis components (motor, gear unit, battery, axles, …) are joined to the car body. With a lifting function and payload capacity of up to 3t, ProLiner guarantees easy, ergonomic access to the underbody. Furthermore, this product can be equipped with onboard illumination, quality screens, air, and power supply. Also customized hangers are possible. Like our ProFleet AGVs, the ProLiner is equipped with scanners, blue spot lighting, covers, and emergency stop buttons for maximum safety in the final assembly area.

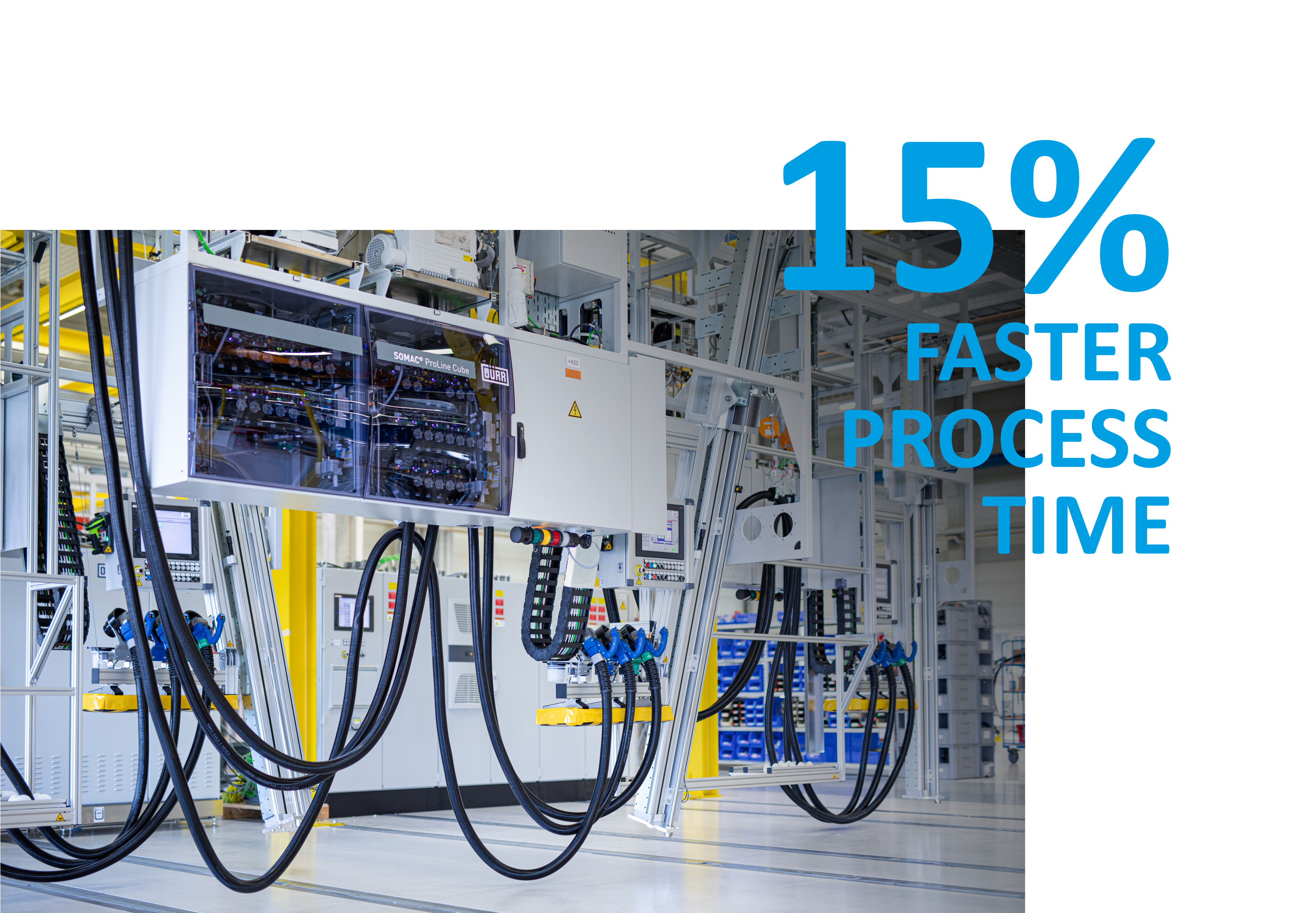

4. ProLine Cube

To fill vehicles efficiently with all required media, the ProLine Cube filling system is essential. This modular filling system of the new generation optimizes material flow and reduces process times by up to 15%. Its compact system integrates multiple filling functions in a block design with fewer pipes and fittings. One base unit support up to 4 consoles, ensuring a flexible layout across greater distances. Together with the ergonomic G4 Blue adapter, the Somac® ProLine Cube imporves the overall equipment effectiveness (OEE) of the filling equipment as well as individual media and media combinations by simplifying maintenance and optimizing availability and process quality.

What truly elevates the ProLine Cube is its integration with Dürr’s DXQ software suite. Using DXQequipment.monitoring, filling parameters across all stations are centrally managed and visualized through a single interface. This eliminates the need for manual configuration at each station and allows for the creation and combination of up to 20 parameter sets. Adjustments can be made quickly and centrally, significantly reducing setup time and minimizing errors. In addition, DXQprocess.analytics enables real-time monitoring and historical analysis, helping to identify process deviations, pinpoint root causes of anomalies, and support predictive maintenance strategies. The result: a highly transparent and efficient filling process that improves quality and optimizes resources.

5. x-combined

Efficient vehicle testing in final assembly depends on consolidating multiple testing tasks in one single system. Enter x-combined—a new, all-in-one test stand that combines wheel alignment, brake testing, and sensor testing. Optional features include headlight adjustment and driver assistance system calibration. This makes x-combined the first all-in-one test stand ever.

All tests and adjustments can be carried out manually or fully automatically, without a driver in the vehicle. The main component of the x-combined is a newly developed wheel support that allows for wheel alignment, brake, and sensor tests to be carried out on a single test stand, reducing the number of test stations, process times, space requirements, and infrastructure measures. For this test stand no pit is necessary which leads to less building requirements. A standout feature is the newly developed x-3Dbalancer, an optical steering wheel balancer that combines mechanical accuracy with non-contact, force-free measurement. Using a collaborative robot, the 3D sensor positions itself at the driver’s side window of the vehicle for idea measurements.

To complement x-combined, Dürr offers DXQvehicle.analytics — a software module that enhances rear axle setting precision. This Closed Loop analytics module was specifically developed to automate the control at rear axle setting stations. By synchronizing axle data with measurement results — based on vehicle type and identification number — the system calculates correction values automatically. These values can be conveniently transferred to the rear axle setting stations via a web interface, improving setting accuracy in advance. This intelligent solution significantly increases first-run rate for rear axle settings and reduces adjustment time at the wheel alignment stand, making the entire testing process faster, more accurate, and less dependent on manual intervention.

With our innovative final assembly solutions, Dürr is ready to meet the demands of the future. Whether it’s new vehicle models, different drive systems, or emerging construction methods, Dürr equips you to handle every production modification with this flexible concept also perfectly supports your ideas for next-generation vehicle architectures.