Nanofiltration: Tested and proven

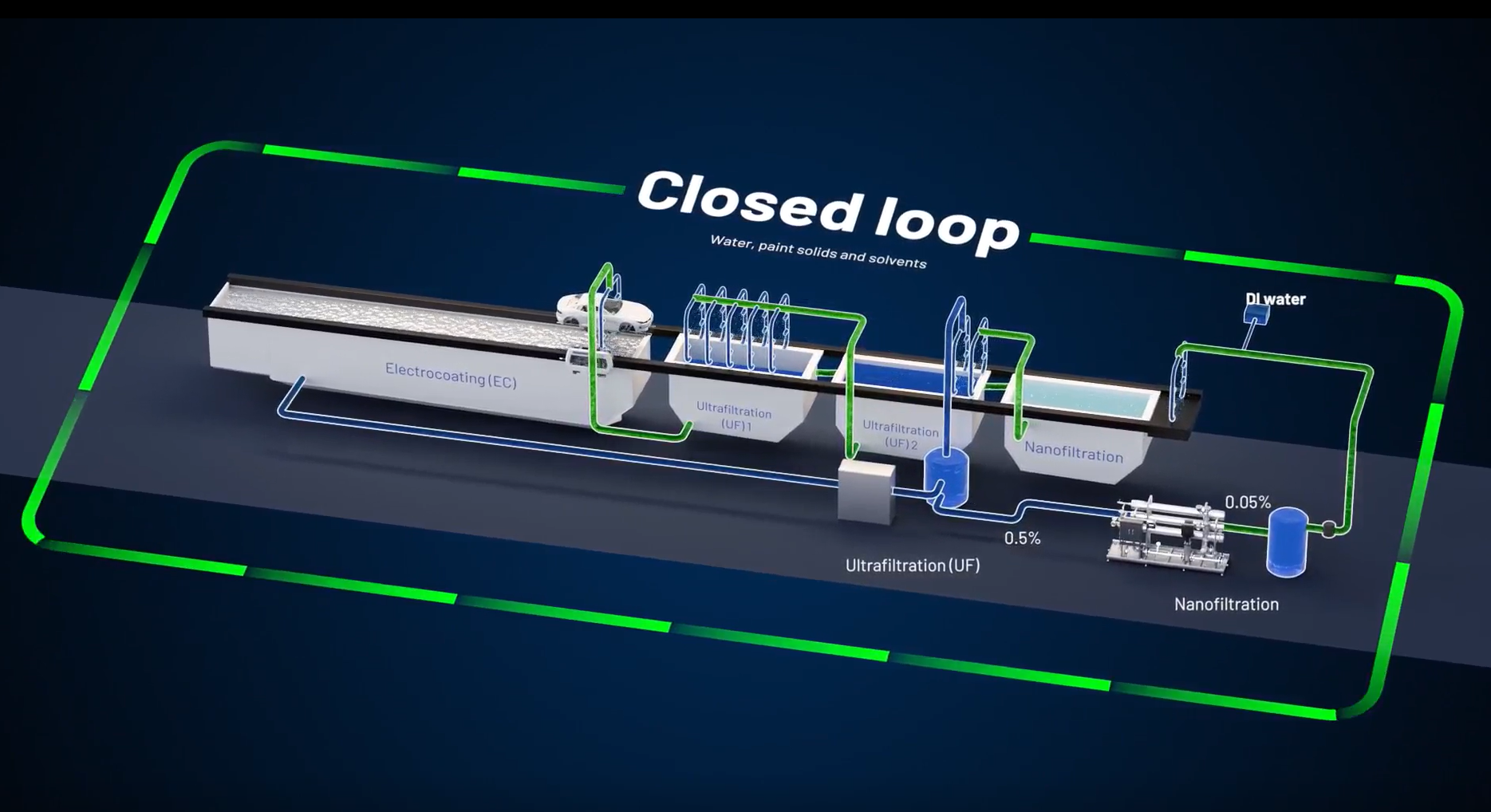

Nanofiltration is a highly efficient membrane process for purifying and recycling liquids. In cathodic dip coating (KTL), it acts as an additional filter stage after ultrafiltration. This reduces the consumption of deionized water (DI water) and simultaneously reduces the amount of wastewater.

The process works similarly to reverse osmosis: the pre-purified water – known as ultrafiltrate (UF) – is forced through special membranes under pressure. These membranes have a pore size of between 1 and 10 nm, which enables sustainable separation at low pressure and thus low energy consumption. The result is particularly clean water that almost reaches the quality of DI water.

Nanofiltration in the cathodic dip coating process

The final rinsing process in cathodic dip coating is particularly crucial for surface quality. Contamination by solids or microorganisms can lead to expensive rework. In conventional cathodic dip coating systems, high-quality deionized water is used for rinsing at the end of the process – often in large quantities and without recirculation. This means high water consumption, high costs, and a lot of wastewater.

With nanofiltration, the process is different:

1. Treatment of the rinse water

After dip coating, the so-called ultrafiltrate – i.e., the pre-purified water – is removed from the ultrafiltrate tank. This water still contains small amounts of dissolved and undissolved substances.

2. Two-part use of the ultrafiltrate

The ultrafiltrate is divided into two streams: One part is used directly for rinsing at the outlet of the last UF rinsing stage. The other part is fed to the nanofiltration unit.

3. Nanofiltration

In the nanofiltration unit, the water is pressed under pressure through special nanomembranes. These membranes are so fine that they retain even the smallest particles and molecules. This results in two new streams:

- Nanofiltrate (permeate) – a particularly pure water that almost reaches the quality of DI water (<0.05% solids content)

- Concentrate – contains the retained substances.

4. Recycling and cascading

The nanofiltrate is collected in a separate tank and fed into the final rinse stage via spray rings – instead of fresh DI water. From there, it is cascaded: it flows from the final rinse stage to the previous one. Finally, it returns to the cathodic dip coating tank, where it is reintegrated into the process.

At the same time, the process is resource-efficient, safe, and economical:

- Up to 75% savings in operating costs

- Up to €86,000 in savings per year in Europe

- Up to 21,000 m³ less DI water consumption per year (equivalent to more than 155,000 bathtubs or approximately 84 Olympic-sized swimming pools)

- Reduction in waste

- Improved process quality through constant water purity

Safety through pilot tests – trust through experience

The performance of nanofiltration depends largely on the chemical composition of the paint used. Different types of paint can vary significantly in their reaction to the filtration process. To ensure that nanofiltration works reliably under real-world conditions, Dürr offers pilot tests.

A compact, mobile nanofiltration unit is installed directly at the customer's site – without major construction work or production interruptions. The system is ready for use within a few hours and can be operated for a period of three to six months. During this time, important parameters such as solids content, pH value, and conductivity are continuously measured and documented in both the nanofiltrate and the concentrate.

This data not only provides valuable insights into process stability but also enables the selection of the optimal membrane configuration for the respective paint type. Especially in cases of individual requirements or new projects, piloting provides a reliable basis for well-informed decisions.

The pilot tests were supervised by the vehicle manufacturer. Dr. Julia Schuchardt, Head of Process Development for Coating Technology and Corrosion Protection at Mercedes-Benz AG, draws a thoroughly positive conclusion:

“The results clearly show that the entire nanofiltrate can completely replace the fully desalinated water (VEW) used to date through cascading. In addition, we were able to identify potential savings that arise in the conventional process as wastewater during the final VEW rinse. The nanofiltration process reduces the amount of chemicals entering wastewater treatment and at the same time makes an important contribution to achieving our sustainability goals in the area of water consumption.”

The pilot project illustrates how innovative technologies can contribute to resource conservation and process optimization.

Dürr continues to support its customers even after installation and commissioning. Customers who opt for the service package receive three visits per year from Dürr service staff, who check and optimize the performance of the nanofiltration plant and the KTL plant.