Mission complete: Heat Pump World Senica

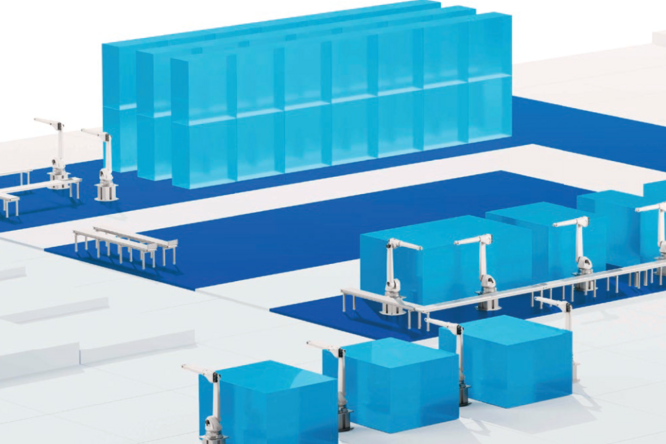

Dürr Consulting has long been active as a management and operations consultant in the technical production environment, supporting customers from a wide range of industries, including mechanical and plant engineering, electronics, energy, and automotive. The consultants relied on proven planning methods combined with innovative digital planning and simulation tools to ensure an efficient planning process and virtually verified results.

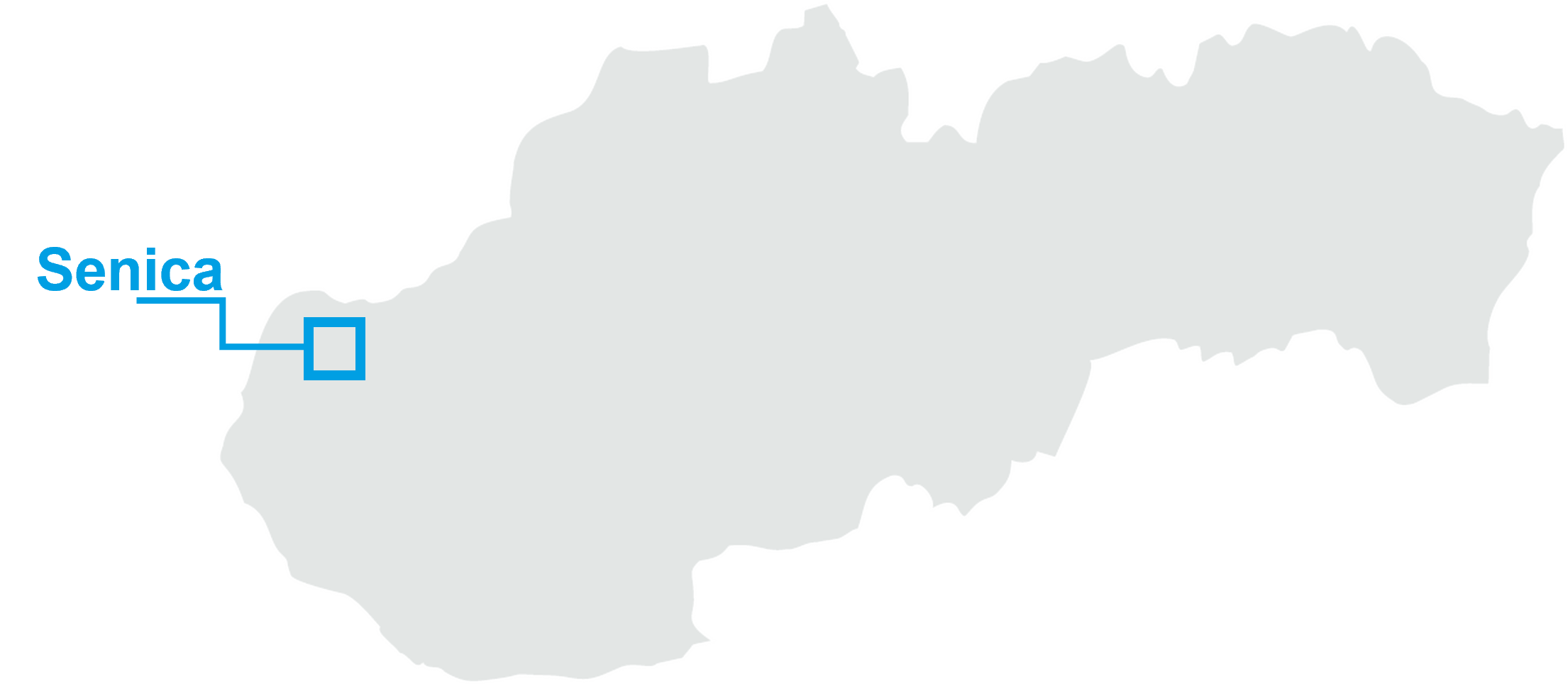

For these reasons, the German heat pump manufacturer Vaillant Group, based in Remscheid, commissioned Dürr Consulting with the planning and implementation of its new factory in Senica, Slovakia. The planning of “Vaillant Group Heat Pump World Senica” is not the first joint project —in fact, it marks the culmination of many years of cooperation with Vaillant. “We had a really positive and productive working atmosphere,” emphasizes Radovan Pristavok, plant manager at Vaillant's new production site. “Dürr Consulting not only contributed valuable expertise in organization and execution but also drew on its in-depth understanding and know-how for technical assessments in automation and overall process planning.”

Experience and expertise in all areas

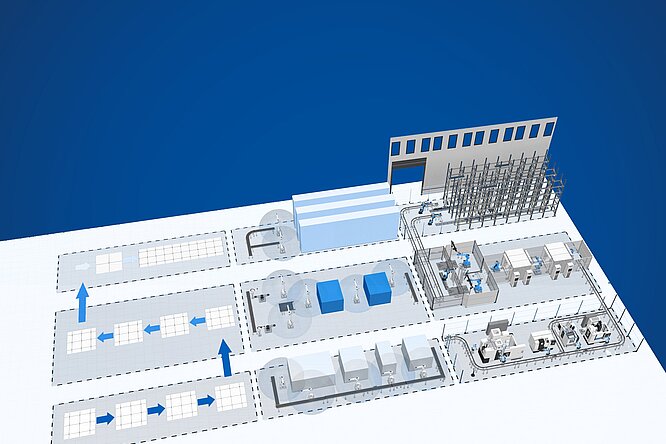

Dürr Consulting oversaw the entire process from the start of planning in 2020 to the start of production, working closely and collaboratively with Vaillant's factory planning team. It all began with the pre-selection of potential production sites based on criteria such as energy supply and transport links. The consulting team then supported layout planning for various production areas, including administration buildings and access roads. Dürr Consulting also designed the selection process for the general contractor and monitored time, costs, and quality standards during the construction phase.

At the beginning of 2024, the Vaillant Group and Dürr Consulting reflected on the project in a joint “lessons learned” session to analyze the challenges and successes and apply the findings to future factory planning. “Heat Pump World Senica is a highlight for us for several reasons,” emphasizes Fabian Thomas, consultant at Dürr Consulting. ”We were involved in every phase of the factory's construction. We worked closely with Vaillant on planning and implementation and were always on site in Remscheid or Senica. This project shows that we can implement large-scale projects with the highest standards of quality and innovation in a wide range of industries.”

Highest international sustainability standards

Building the new plant sustainably and in a climate-friendly way was important to the Vaillant Group. Since 2016, the company has strategically focused on environmentally friendly heat pump technology. The factory is part of this strategy and represents an investment in the future. For example, the factory uses only electrical energy from renewable sources and heats the plant with its own heat pumps. In addition, “Heat Pump World Senica” has been awarded the “BREEAM excellent” rating. The Building Research Establishment Environmental Assessment Methodology (BREEAM) is the world's leading sustainability assessment method for the built environment and infrastructure.

Factory already honored

The new factory has also been recognized as “Building of the Year” by the Association for the Development of Slovak Architecture and Construction (ABF Slovakia). The annual award, presented live on Slovak public television, honors functional and architecturally outstanding buildings.