Bundled power: Dürr at the Battery Show Europe 2025

New concept for lithium-ion battery cell production

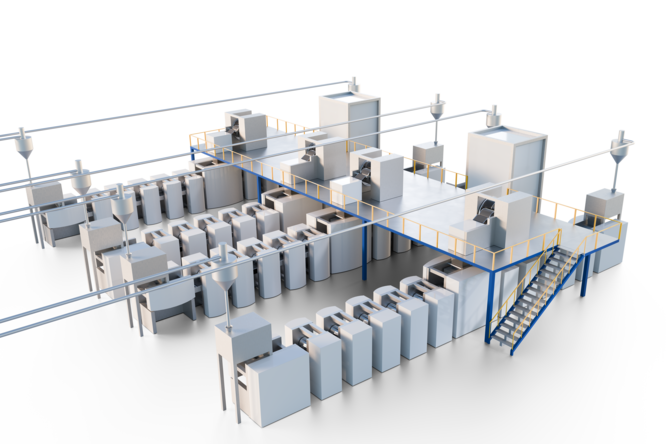

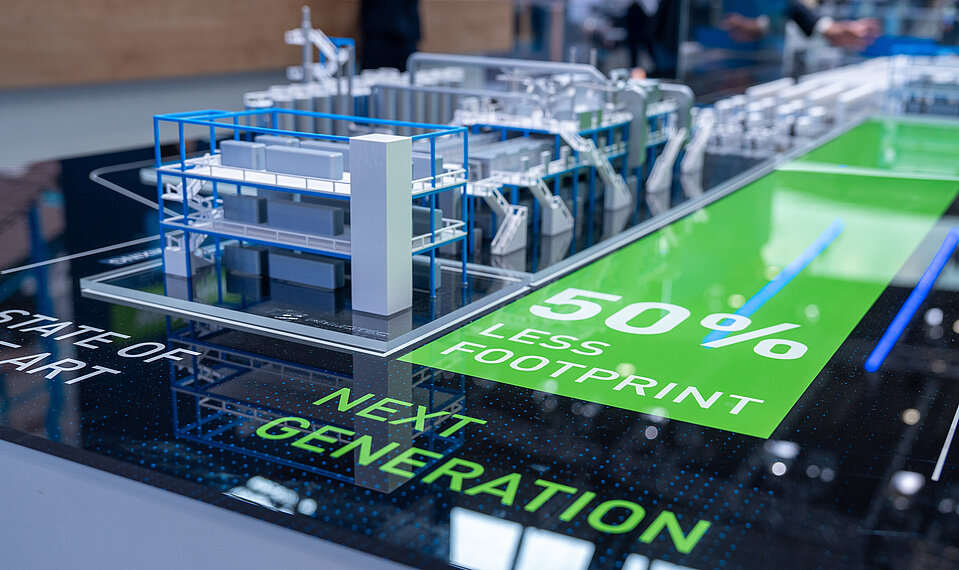

Also a visual highlight: in the front area of the trade fair stand, visitors were able to explore an almost 5-meter-long 3D-printed model of the new concept factory for lithium-ion battery cell production and visit it virtually on transparent touchscreens. The new concept combines technologies from Dürr and the mechanical engineering company GROB, with whom Dürr has been cooperating in the field of battery production since 2022.

The model contrasts two variants: A state-of-the-art process and the new concept with innovative dry coating of the electrodes from Dürr and high-performance technology for cell assembly from GROB. The difference is immediately apparent on the model: 50% less space and energy are required with the new concept. For battery manufacturers, this means significantly higher space efficiency and lower operating costs. The main reason for this is the dry coating, as no drying process and no solvent recovery and treatment are required.

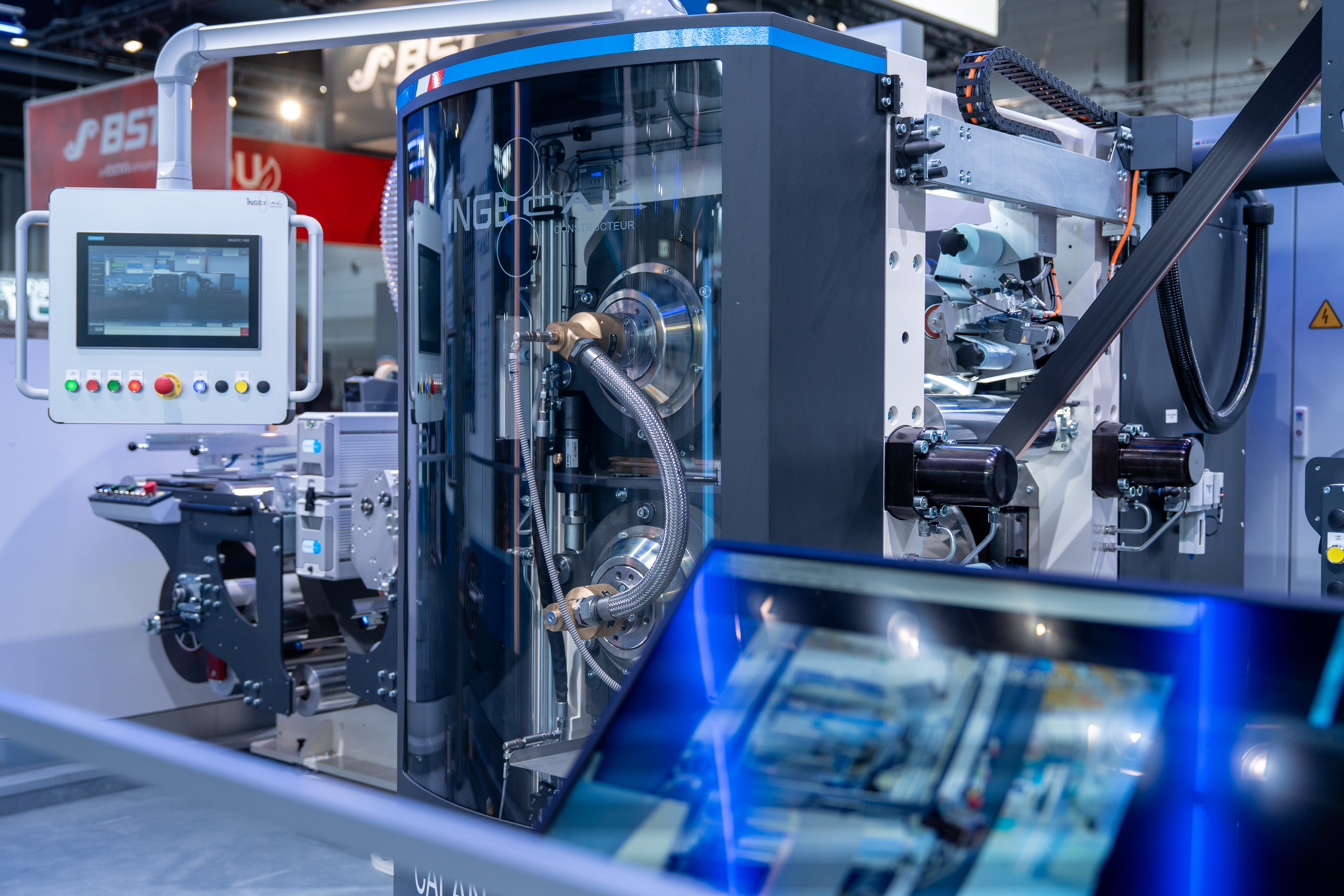

High-precision densification with calenders

Dürr subsidiary Ingecal from France presented a calendering machine with live demonstrations that filled the trade fair stand. The calender feeds the electrode material through two rollers during the production process and compacts it. The X.Cellify-EC calenders, which are part of the newly introduced X.Cellify product family, operate with high precision: two sensors measure the distance between the two rollers to an accuracy of 0.5 µm, resulting in a very uniform layer thickness. The machines are used for both wet coating and dry coating to densify the active material.

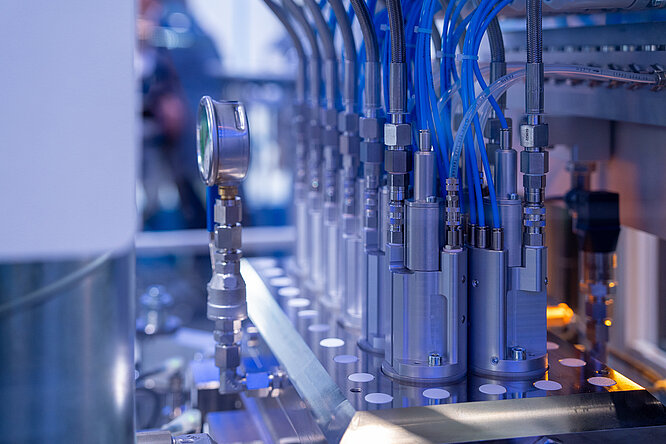

New technology for electrolyte filling

Dürr’s subsidiary Dürr Somac presented a newly developed process for electrolyte filling of battery cells, which visitors were also able to observe on a running machine. In contrast to the conventional process, with X.Cellify PF the cells are filled directly at two to three times higher pressure in just one step. The process design enables precise dosing and shortens the filling process as well as the subsequent penetration of the electrolyte into the active material.

Precise application of adhesives, sealants and thermally conductive materials in battery production

Dürr as a supplier combines its extensive application expertise in the bonding and sealing of automotive batteries. A modular system for the application of adhesives, sealants and thermally conductive materials ensures high quality, flexibility and adaptability for different viscosities and mixing ratios. The portfolio includes the EcoRAM drum pump shown at the trade fair, which conveys highly viscous media directly from the original container to the dispenser.

End-to-end digitalization

Dürr subsidiary iTAC supplements the system technology with end-to-end digitalization of the production process. The MES/MOM software from iTAC can be used to control and plan all production steps in battery manufacturing. Important functions include traceability and quality analysis in order to avoid errors in production. The result is production with high overall system efficiency.

Battery production technology from BBS

BBS, also part of the Dürr group, presented its portfolio of assembly and testing systems for battery cells, modules and packs at the Battery Show Europe. Visitors to the trade fair had the chance to watch a stacking unit in action.

Our booth was a hive of activity for three days and our colleagues on site were in constant conversation. Current and potential customers visited us to discuss upcoming projects. The VDMA organized tours, which included us on the agenda, and ensured additional peaks in activity.

On the afternoon of the first day of the trade fair, the relevant German and international trade press were given a comprehensive insight into our technologies. As part of a press event, Dr. Jochen Weyrauch and German Wankmiller (CEO GROB) presented the cooperation and market positioning as well as the joint concept factory, after which Bernhard Bruhn (VP Global Business Unit Lithium-Ion Battery) and Christian Lisiecki (Director Business Unit Battery Systems at GROB) guided the journalists through the various stations of the trade fair booth.

The successful presence at the trade fair was an important step towards establishing Dürr together with its partner GROB as leading system providers for battery production systems in Europe and North America. With our expanded portfolio of high-availability machines and systems, together we cover almost the entire value chain for battery cell production with our own technologies.

After the show is before the show: In October, we are heading to the battery shows in the USA and India.